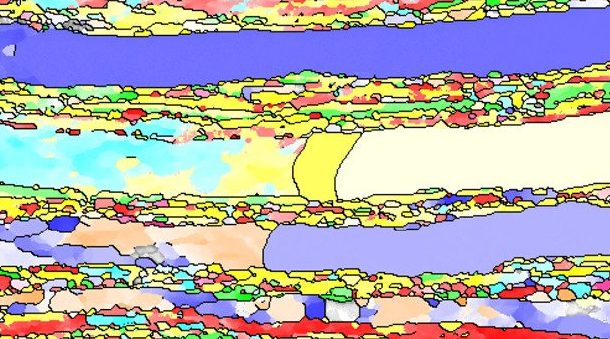

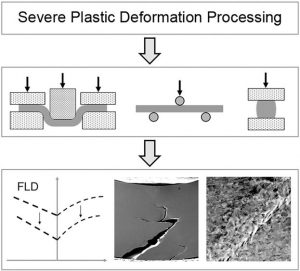

Severe plastic deformation methods can be used to achieve ultrafine-grained (UFG) or nanocrystalline (NC) microstructures in metallic materials with extraordinary mechanical properties. At EUROMAT 2017, the field of severe plastic deformation (SPD) was covered by two symposia, C10 “Thermomechanical Processing, Severe Plastic Deformation and Nanostructuring” and B4 “Advanced properties of SPD‐processed metallic materials”, resulting in eight scientific sessions reflecting the continued interest in scope as well as the importance of research and development in this diverse field.

Severe plastic deformation methods can be used to achieve ultrafine-grained (UFG) or nanocrystalline (NC) microstructures in metallic materials with extraordinary mechanical properties. At EUROMAT 2017, the field of severe plastic deformation (SPD) was covered by two symposia, C10 “Thermomechanical Processing, Severe Plastic Deformation and Nanostructuring” and B4 “Advanced properties of SPD‐processed metallic materials”, resulting in eight scientific sessions reflecting the continued interest in scope as well as the importance of research and development in this diverse field.

A special section of Advanced Engineering Materials, guest-edited by Andrea Bachmaier, Anton Hohenwarter, Heinz Werner Höppel and Julia Ivanisenko, presents highlights from these symposia. The current state of research in the field of ultrafine grained metallic material is presented in three review articles and eleven original research papers.

The review article by Bruder tackles important problem of deformability of SPD‐processed nanomaterials which is crucial for their applications as structural materials. In this context two contributions about superplastic behavior of ultrafine grained materials included in this section (by Bobruk and Lee) illustrate the good perspectives for achieving low temperature and high strain rate superplasticity.

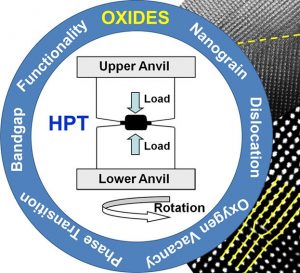

Two further articles are related to the microstructure formation mechanisms in austenitic stainless steels during SPD and subsequent annealing. In particular, in the paper by Belyakov various aspects of dynamic recrystallization at multiple multidirectional forging are discussed, whereas the contribution of Krawczynska is devoted to the influence of the high hydrostatic pressure on the development of static recrystallization after high pressure torsion. The review article by Skrotzki summarizes the research on metallic nanocomposites produced by accumulated roll bonding (ARB).

Several further contributions provide various examples of successful application of ARB and high pressure torsion for  composite materials manufacturing using quite interesting materials combinations like Al and Al2O3 ceramic (Ivanov), Al and steel (Kümmel) or Al and Ti (Schunk), and Ni and carbon nanotubes (Bachmaier). In the communication by Kwiecien a new procedure to produce metallic laminated composites based on application of surface mechanical attrition treatment and subsequent high‐strain rate compression is introduced.

composite materials manufacturing using quite interesting materials combinations like Al and Al2O3 ceramic (Ivanov), Al and steel (Kümmel) or Al and Ti (Schunk), and Ni and carbon nanotubes (Bachmaier). In the communication by Kwiecien a new procedure to produce metallic laminated composites based on application of surface mechanical attrition treatment and subsequent high‐strain rate compression is introduced.

The review article by Edalati provides a deep insight into the new application area of SPD for processing and consolidation of metallic oxide powders, which enhances their physical properties, for example, allows to tune a band gap. And in the final paper by Kriegel, completing this section, the analysis of thermal stability of the athermal ω phase obtained by quenching of Ti–4 wt% Fe alloy is performed in comparison with that of ω phase formed at high pressure torsion.

All contributions are now available for free for a limited time. Enjoy reading!