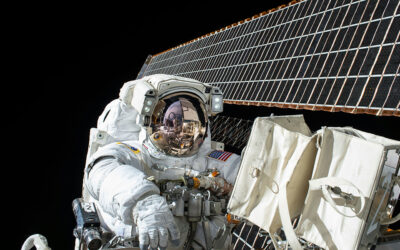

The advent of minimally invasive robotic surgery has been a game changer for patients the world over. Many common procedures are now performed using miniaturized surgical instruments that can be inserted into the patient’s body through small incisions that measure less than a quarter of an inch.

Innovative developments in surgical tools, procedures, and AI assistants have led to improved safety of many common procedures, including reduction in blood loss, minimal complications, and improved recovery times – and things are only getting better, says Xiaowen Kong, a Ph.D. candidate at University of Science and Technology of China and City University of Hong Kong who studies surgical robotic systems.

“In robotic surgery, surgeons need to adjust the laparoscope frequently to provide a better field of view, which distracts the surgeons and leads to an intensive workload,” said Kong. Laparoscopes are thin, tube-like instrument used to view tissues and organs inside the abdomen during what surgeons colloquially call “keyhole surgeries”. They contain a light and a camera lens for diagnosis and navigation and may also have a tool mounted to remove tissue, such as an inflamed appendix.

“Developing methods to manipulate surgical instruments automatically in robotic surgery is an effective way to reduce the burden of surgeons, which is also the development trend of intelligent surgical robotic systems in the future,” said Dong Sun, chair professor at the Department of Biomedical Engineering in City University of Hong Kong.

In a recent study published in Advanced Intelligent Systems, Sun, Kong and their collaborator Hangjie Mo, developed a data-driven control method to help laparoscopes automatically adjust the field of view in robotic surgery.

Automatic control

In a surgical robotic system, surgical instruments are fixed at the end of the robot arms and controlled by the surgeons. “Considering such multi-robot arms lead to the limited workspace, we introduced a continuum laparoscope to replace the traditional rigid laparoscope and its related robot arm,” said Sun.

The data-driven approach relies on a large collection of data to estimate a continuum laparoscopic model. “Generally speaking, this data-driven method is also a control method, which relies on a large amount of data to estimate the model of the system to achieve the purpose of accurate control,” said Kong. “With sufficient input-output data, a data-driven model can describe the system’s behavior throughout its entire operating range.”

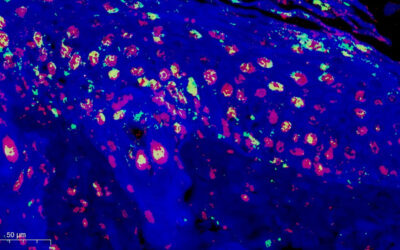

Precise visual feedback is also crucial. Using a deep learning method, the system can predict the position of key points on the surgical instruments, allowing it to identify their precise location and readjust as needed.

Simulations and experiments showed the feasibility of the proposed data-driven control method to adjust the laparoscopic view automatically during robotic surgery and can also satisfy the clinical requirements. By automating the task of laparoscopic view adjustment, the team hopes to lay a foundation for the development of a more intelligent surgical robot systems.

“Despite the promising results achieved in this work, other surgical subtasks also need to be explored, such as automatic suturing, knot tying, and so on,” said Sun. “We will work to develop a more intelligent surgical robot system to reduce the burden of surgeons by the automatic surgical procedures.”

Reference: Xiaowen Kong, Hangjie Mo, Erbao Dong, Yunhui Liu, and Dong Sun, Automatic Tracking of Surgical Instruments with A Continuum Laparoscope Using Data-driven Control in Robotic Surgery, Advanced Intelligent Systems (2022). DOI: 10.1002/aisy.202200188.