Advances in printed flexible electronics will impact robotics, biomedical devices, and many more industries. Research on methods and materials to fabricate these devices is vital.

In their paper in Advanced Materials, Professor Steve Park and colleagues from Korea Advanced Institute of Science and Technology (KAIST) and co-workers from Pohang University of Science and Technology (POSTECH) and Kwangwoon University demonstrate a novel microstructured blade for solution shearing to produce thin-film transistors.

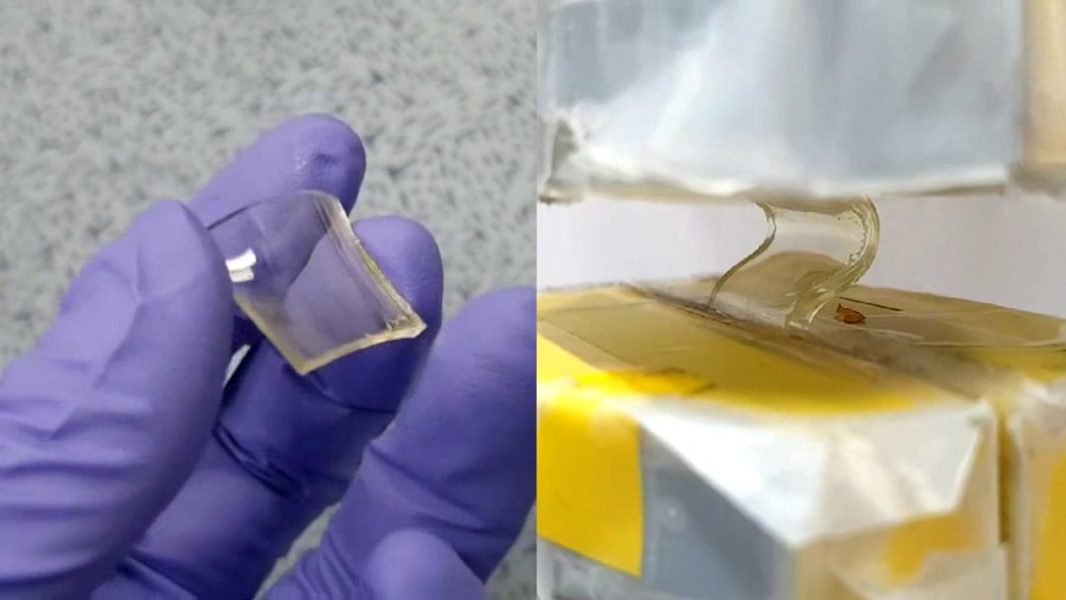

A flexible, durable, and solvent-resistant inorganic polymer (allylhybridpolycarbosilane, or AHPCS) was used to fabricate the microstructured AHPCS shearing blade. The wettability of the AHPCS micropillar surface is tunable.

By controlling the shearing rate and the substrate temperature, crystal growth can occur along the moving blade. Curvature of the meniscus is greatest at the center of the pillars and between the pillars, which is suggested to increase the likelihood of nucleation in those regions.

Field-effect transistors with microstructure dimensions from 10 to 60 µm were fabricated using this shearing-blade technique. Experiments show that the field-effect mobility increases with increasing microstructure size.

An AHPCS-based shearing blade was fabricated with inherent curvature, which could be used to create thin films directly onto non-planar surfaces, increasing the utility of this technique.

To find out more about using AHPCS microstructured blades for solution shearing, please visit the Advanced Materials homepage.