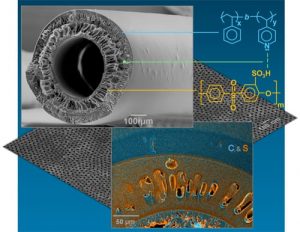

A research group led by Prof. Volker Abetz at Helmholtz-Zentrum Geesthacht and University of Hamburg in Germany has introduced one new dimension to the fabrication of non-solvent induced phase separation- (SNIPS) based isoporous block copolymer membranes. Ph.D. student, Nazia Noor, together with her colleagues, has prepared a double layer hollow fiber where an isoporous surface of polystyrene-block-poly(4-vinylpyridine) (PS-b-P4VP) is mounted on a support layer of another polymer material in one step by a co-extrusion method.

A research group led by Prof. Volker Abetz at Helmholtz-Zentrum Geesthacht and University of Hamburg in Germany has introduced one new dimension to the fabrication of non-solvent induced phase separation- (SNIPS) based isoporous block copolymer membranes. Ph.D. student, Nazia Noor, together with her colleagues, has prepared a double layer hollow fiber where an isoporous surface of polystyrene-block-poly(4-vinylpyridine) (PS-b-P4VP) is mounted on a support layer of another polymer material in one step by a co-extrusion method.

The work is featured on the cover of issue 5 of Macromolecular Rapid Communications.

Purification is a term which is associated with every basic need of mankind. We need pure food, pure water, pure medicine, etc. For ultra-pure commodities, the purification medium has to be very selective to impurities. Maximising purity while minimizing energy input is still a major challenge. Block copolymer self-assembly is a key tool for making a very selective barrier between pure and impure entities. This process of membrane fabrication, where the self-assembly of the block copolymers winds up with SNIPS, offers an easy and intriguing way to prepare isoporous structures on the selective surface of the membranes.

Co-extrusion is preferable for preparing double layer hollow fibers, because of the ease of processing with less expense of materials, but the double layer hollow fiber fabrication, where the isoporous PS-b-P4VP selective layer is employed to hook up to the support layer of other polymers, always extrudes out with delamination of the layers. After analysis of the results by Edisonian approach, the research group has found that, along with the processing parameters, interfacial bonding between the layers can solve the problem of nonadherence at the interface of the layers. For this they functionalize the support layer material with the sulfonic acid group (-SO3H).

During processing of the fiber, the two layers stick together by hydrogen bond formation between the sulfonic acid groups and the basic pyridine groups of the respective layers. It is done in a delicate way so that the bond formation does not get disturbed in the spinning line during the fiber formation. The resultant fibers are stable for handling, although the continuous phase of the selective layer is of polystyrene, which is a rather brittle material.

“It is a very intricate method to have hold on the chemical bond formation while optimizing the processing parameters for fiber spinning and keeping the isoporous surface structure intact”, says Prof. Abetz. “And we are quite excited.”

For the upscaling of the membranes of sharp molecular weight cut-off from the tailor-made polymers, the transformation into hollow fiber geometry would render more efficient and sturdy membranes in an economic way, if they can be spun with a support layer of suitable polymer materials. The welding of the PS-b-P4VP layer on the support layer by in-situ bonding opens up the possibility to upscale this kind of highly selective membrane, not only in hollow fiber but also in other geometries.