Polymer dielectrics are an interesting alternative as temporary masks or permanent insulators in microelectronics manufacturing, since they offer much simpler fabrication and generally lower costs with respect to equivalent inorganic materials.

Polymer dielectrics are an interesting alternative as temporary masks or permanent insulators in microelectronics manufacturing, since they offer much simpler fabrication and generally lower costs with respect to equivalent inorganic materials.

In particular, for packaging and wafer passivation, a positive (in the sense that the part of the photoresist that is exposed to light becomes soluble) photosensitive dielectric material that can form thick films would be highly desirable.

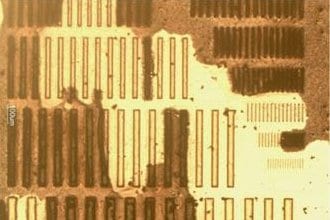

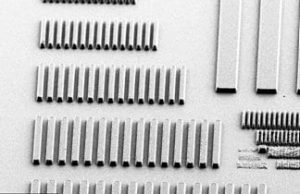

Paul Kohl and coworkers at Georgia Tech and Promerus LLC of Brecksville, OH, in two papers just published in the Journal of Applied Polymer Science have now developed different types of polynorbornene derivatives that can be used for these purposes, and present several advantages over previous materials. Aside from having good optical contrasts, the materials are aqueous developable, doing away with costly and potentially harmful organic polymers during processing.

The first article reports a polynorbornene that is crosslinked with a tetrafunctional epoxy resin, enabling the realization of structures with extremely high contrast ratios, at the price of somewhat longer developing times. The polymers have improved adhesion on the silicon substrates as well, thanks to the crosslinker.

The second paper shows instead a formulation in which diazonaphthoquinone is used to inhibit polymer dissolution before it is exposed to light, eventually producing a material that has good contrast ratio and short development times, and thus could be suitable for industrial applications.