Daido Steel and Honda have become the world’s first companies to achieve the practical application of a hot deformed neodymium magnet containing no heavy rare earth metals. The companies report that it shows high heat resistance properties and high magnetic performance required for the use in the driving motor of a hybrid vehicle. This heavy rare earth free hot deformed neodymium magnet will be applied first to the all-new Honda FREED, scheduled to go on sale later this year.

Neodymium magnets have the highest magnetic force among all magnets in the world and are being used for the drive motors of electric vehicles, including hybrid vehicles. Therefore the demand for neodymium magnets is expected to grow exponentially in the future.

For use in the drive motors of electric vehicles, neodymium magnets must have high heat resistance properties as they are used in a hot environment. Adding heavy rare earth metals (dysprosium and/or terbium) to the neodymium magnets has been a conventional method to achieve such high heat resistance.

However, major deposits of heavy rare earth elements are unevenly distributed around the world, and also are categorized as rare metals; thus, the use of heavy rare earth elements carries risks from the perspectives of stable procurement and material costs. Therefore, a reduction in the use of heavy rare earth elements is a major challenge.

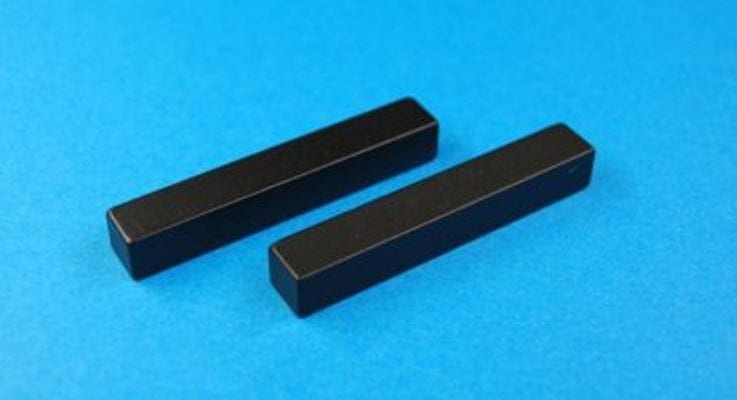

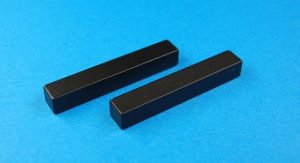

Heavy rare earth-free magnet. Source: Honda Motor

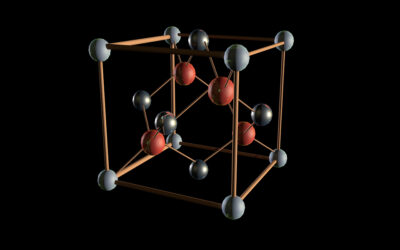

Daido Electronics, a subsidiary of Daido Steel, has been mass-producing neodymium magnets using the hot deformation method, which is different from the typical sintering production method for neodymium magnets. The hot deformation method is a technology that enables nanometer-scale crystal grains to be well-aligned in order to realize a fine crystal grain structure that is approximately 10 times smaller than that of a sintered magnet, which makes it possible to produce magnets with greater heat resistance properties.

This time, Daido Steel and Honda jointly developed new neodymium magnets while Daido Steel further evolved its hot deformation technologies and Honda leveraged its experience in development of drive motors and revised the shape of the magnet. Through these joint development efforts, the two companies achieved, for the first time in the world, a practical application of a neodymium magnet that contains absolutely no heavy rare earth metals, yet has high heat resistance and high magnetic performance suitable for use in the drive motor of hybrid vehicles.

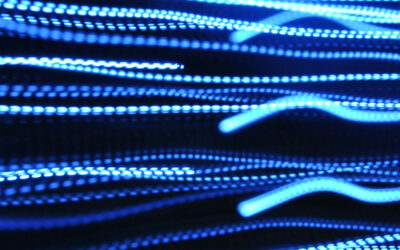

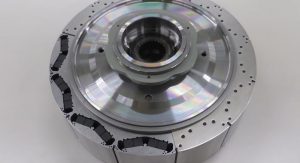

A rotor for the i-DCD drive motor. Source: Honda Motor

Moreover, Honda designed a new motor which accommodates this new magnet. In addition to the shape of the magnet, Honda revised the shape of the rotor to optimize the flow of the magnetic flux of the magnet. As a result, the hot deformed neodymium magnet became usable for the drive motor of a hybrid vehicle, demonstrating torque, output and heat resistance performance equivalent to those of a motor that uses the conventional type of magnet.