Self-healing polymers can respond to a traumatic mechanical event (cut, fracture or deformation) to restore the original material and its properties. A variety of architectures have been explored for these materials, from reversible Diels-Alder reactions to hollow rod and encapsulation methods. Often these architectures share the problem that the temperature required for the recovery is quite high (often around 100 degrees Celsius).

Alternatively there are supramolecular materials, which are naturally self-healing as they are constituted of reversible non-covalent bonds; however, these suffer from low mechanical strength, which drastically limits their applications in structural materials.

Having a material which contains both supramolecular and covalent bonds could be advantageous to tune the properties of the material more towards self-healing or towards mechanical strength, achieving levels for both properties that could be useful for particular applications. This is exactly what Russel Varley and co-workers at CSIRO in Australia describe in a new paper published in the Journal of Applied Polymer Science.

Having a material which contains both supramolecular and covalent bonds could be advantageous to tune the properties of the material more towards self-healing or towards mechanical strength, achieving levels for both properties that could be useful for particular applications. This is exactly what Russel Varley and co-workers at CSIRO in Australia describe in a new paper published in the Journal of Applied Polymer Science.

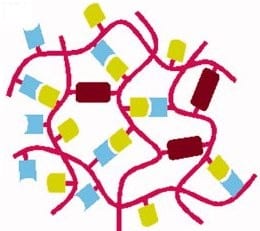

The researchers start from a ureido-amide thermoplastic elastomer, which has been shown in the past to exhibit self-healing characteristics and is a supramolecular material (since it is kept together by multiple hydrogen bonds), and react it with an epoxy resin. A higher percentage of epoxy, which crosslinks forming covalent bonds with the amide groups in the supramolecular matrix, produces a material that has somewhat lower recovery but better mechanical properties. In any case, substantial levels of healing of 62% are achieved even with a material presenting a glass transition above room temperature. This is likely due to the significant molecular mobility within the material, which facilitates self-healing.