In a recent publication in Macromolecular Chemistry and Physics, Prof. Meier and co-workers from the Karlsruhe Institute of Technology, use renewable resources to prepare thermosetting polymer films with tunable mechanical properties.

Decreasing fossil feedstocks and the simultaneously growing global population, accompanied with an increasing demand for energy and resources, stimulate the development of materials from renewable resources. As the polymer sector accounts for a large portion of the chemical industry, the search for sustainable alternatives for polymeric materials is of high interest.

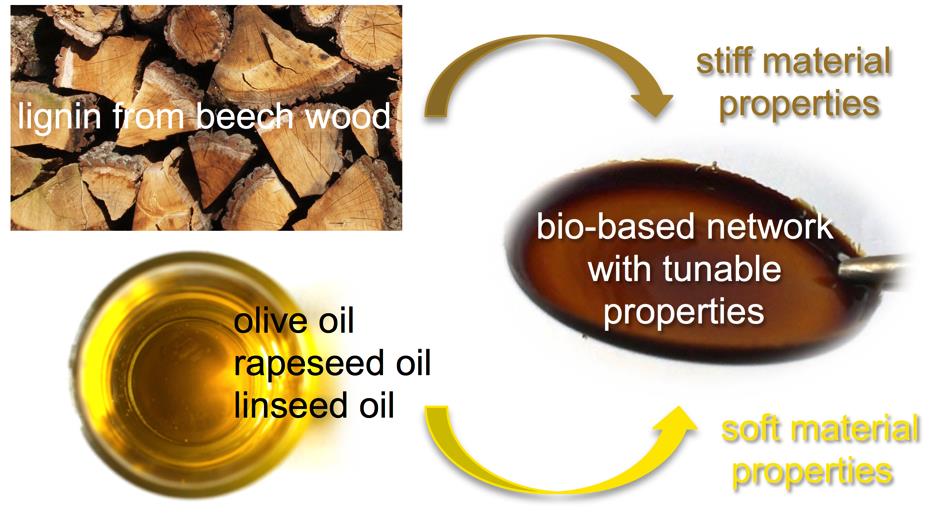

Lignin is one of the most abundant biopolymers on earth and the largest natural resource for aromatic compounds. It can be isolated from wood and other plants via pulping processes. Plant oils, such as olive, linseed and rapeseed oil, constitute another interesting renewable resource with a high availability.

The synthesis of polymer networks containing both renewable resources, which are normally incompatible, is described. For the first time, unmodified plant oils were reacted with a lignin derivative. The lignin modification itself was performed using an environmentally friendly procedure.

The presented approach complies with several of the twelve principles of green chemistry, e.g., less hazardous synthesis, use of renewable feedstocks, and catalysis. The sustainability of the procedure can be further increased using a more environmentally benign solvent to replace a conventional toxic solvent.

The new methodology opens up access to new bio-based materials that have the potential to replace petrochemical products. Due to the chemical and structural differences of the two materials, the resulting mechanical properties of the products depend on the lignin-to-oil ratio and of the type of plant oil used (i.e., amount of unsaturation present). The rigid structure of lignin leads to stiff materials at high lignin content. In contrast, increased plant oil contents yield softer materials.

These exciting results highlight the possibility of combining two structurally different renewable materials to prepare cross-linked networks with varying and tunable mechanical properties, leading to possible applications in different fields of polymer chemistry.