TenCate Advanced Composites, developer and manufacturer of advanced composite materials, provides the Astro Aerospace with thermoplastic composites.

These are used for the AstroMesh deployable mesh reflector on the NASA Soil Moisture Active Passive spacecraft. The reflector uses TenCate Cetex to achieve parabolic shape design, strength, durability, and weight savings.

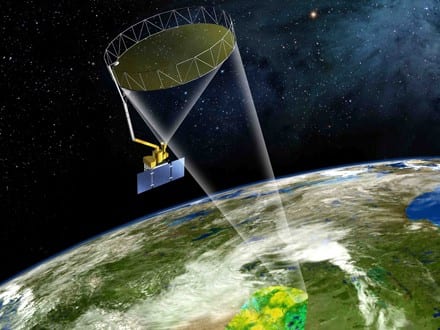

NASA’s Soil Moisture Active Passive (SMAP) spacecraft launched this year will provide global measurements of soil moisture and indicate whether it is frozen or thawed. The data will be used to understand the processes that link Earth’s water, energy and carbon cycles and improve weather and climate prediction models.

The SMAP spacecraft, developed by NASA’s Jet Propulsion Laboratory in Pasadena (California), USA, uses a 6 meter (19 foot) AstroMesh deployable mesh reflector and boom from Astro Aerospace, a Northrop Grumman company. The reflector, which will spin atop the spacecraft at nearly 15 revolutions per minute, provides for total global mapping every 2 to 3 days. The reflector uses thermoplastic composites to achieve the strength, durability, and weight savings needed.

Daniel Ochoa, Product Development Manager at Astro Aerospace states: “TenCate Cetex thermoplastics are integral to the structure of our mesh reflectors as they help to create the parabolic shape of the antenna. The material has been extensively tested as part of the unit prior to flight, and is durable and stiff, which is critical to the functioning of the antenna.”