In the production of next generation biofuels like diesel or hydrogen, algae photobioreactors are expected to play an important role for process optimization. The basic requirements for high-density photoautotrophic micro-algal cultures in enclosed photobioreactors are an efficient gas exchange, a suitable medium composition, and a powerful light source with a suitable light distribution.

In the production of next generation biofuels like diesel or hydrogen, algae photobioreactors are expected to play an important role for process optimization. The basic requirements for high-density photoautotrophic micro-algal cultures in enclosed photobioreactors are an efficient gas exchange, a suitable medium composition, and a powerful light source with a suitable light distribution.

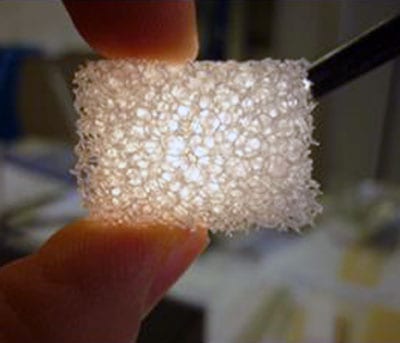

The use of a new class of materials called transparent glass sponges could result in an effective light dispersion through the reactor providing the optimum local light intensity. Advantages like their optical properties, high softening temperatures, and resistance to chemical attacks makes them an ideal candidate for use as the light source in these reactoes. Additionally, due to the high permeability of the open-celled structure, the free flow in the reactor is almost not affected. However, open-celled glass sponges are not commercially available at present.

At the Karlsruhe Institute of Technology (KIT), Germany, a research team are trying to change this – Dr. Ethel C. Bucharsky and coworkers prepared transparent glass sponges using a polymer replica technique that employs polyurethane sponges as templates and commercially available nanoscaled SiO2 powders.

Bucharsky and coworkers found that for the successful implementation of this preparation route concentrated suspensions at around pH 10 revealed the most suitable properties. At pH ≈10 the suspension brings enough particles onto the polymer template for the formation of a stable and self-supporting SiO2 shell. The particulate framework was successfully sintered to a transparent body employing high heating rates and short dwell times. The thermodynamically favored transformation from amorphous into crystalline SiO2 is suppressed.

The structural characterization of glass foams was conducted using magnetic resonance imaging (MRI). The three-dimensional structure of the monolithic network, their geometrical dimensions as well as specific surface area and pore diameter was determined from MRI data. These topics are crucial for the use of foams in photobioreactors. Results and analysis of these data will be published in a forthcoming paper.