An international research team led by Professor Jodie Bradby of Australian National University (ANU) has created a new type of silicon that better uses sunlight and promises to cut the cost of solar technology. The researchers say their invention could help reduce the costs of renewable electricity below that of existing coal power stations, as well as lead to more efficient solar cells.

In the study, silicon was used as the raw material for solar cells due of its abundance, low-cost, and non-toxicity. “But the standard form of silicon does not use all available sunlight,” adds Bradby. “Just by poking silicon with a tiny, hard tip, we’ve created a more complex silicon capable of absorbing more sunlight than the standard type commonly used in solar cells. We have proved that we can easily make this new kind of silicon – previously thought unobtainable under normal room temperature and pressure – which could be used for making more efficient solar cells and lead to cheaper energy.”

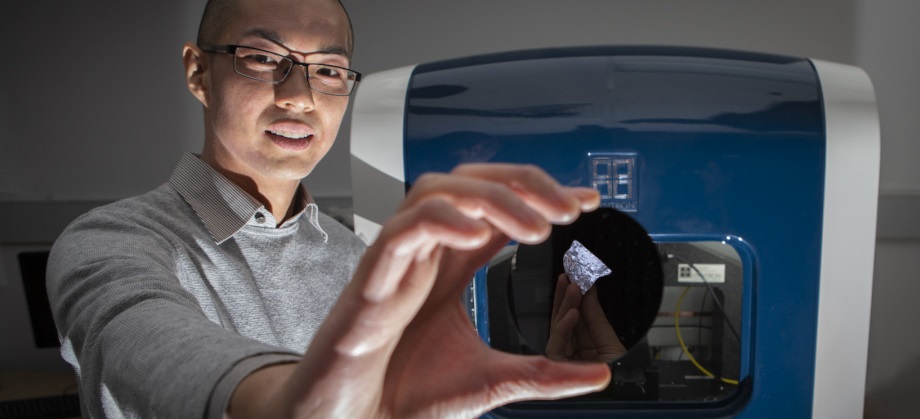

Dr. Sherman Wong worked on the study for his PhD at ANU and said that, at the time, the team was exploring a little-known property of silicon, which is its ability to exist in different crystal forms.

“Silicon can take many crystal forms that have different and useful properties,” said Dr. Wong, who is now at RMIT University. “The new type of silicon we’ve created is called r8-Si. Instead of the atoms being square or cubic like in standard silicon, it’s more complex, shaped a bit like a diamond on playing cards, only it’s in 3D. It’s an exciting field and there is a multi-billion dollar industry built around silicon manufacturing, so silicon is a super important material that’s worth optimizing.”

Professor Bradby said the team would use unique high-pressure facilities to develop ways of making enough material to produce a prototype solar cell.

“We now need to measure how well this material absorbs light and behaves electrically,” she explained. “We also need to scale up and then work on integrating this material into existing solar industries. This will take another three to five years.”