Longer battery life and higher energy density within wide operational temperature windows are always the aims of battery research efforts.

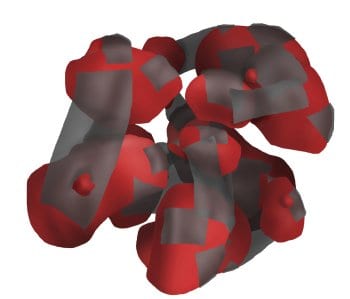

Led by Dr. Donghai Wang, a research group at The Pennsylvania State University has developed a novel negative electrode material for lithium ion batteries: Phosphorus-graphene nanosheets hybrid. This alloy was prepared via simple ball milling graphene stacks and red phosphorus. Different from white and black phosphorus, red phosphorus is chemically stable, abundant, relatively cheap and eco-friendly, which make it a promising candidate for high-energy lithium-ion batteries. Large red phosphorus particles are grounded into much smaller once and hybridize with graphene nanosheets to form a 3D integrated network, which significantly improves the conductivity. The material delivers a very high specific capacity of 1400 mAh/g and a cycling stability at room temperature, which is nearly 4 times higher than that of commercial Li-ion graphite materials. Moreover, even at higher temperatures (60°C), the hybrid anode still exhibits an outstanding cycling stability with a capacity of 1650 mAh/g.

These attributes, along with the facile and general ball milling method and low cost starting materials render this hybrid a promising negative electrode candidate for the next generation lithium-ion battery.

Read the whole research article now in the latest issue of Advanced Science.