In many synthesis reactions, plasma provides a convenient alternative to thermal heating or chemical reactants. Noticeably, plasma‐enhanced chemical vapor deposition (PECVD) processes can lead to the simultaneous low‐temperature synthesis and deposition of crystalline metal oxide thin films on polymer substrates or ensure the “polymerization” of chemically non‐polymerizable precursors. Nevertheless, due to the intrinsic nature of plasmas, a non‐negligible number of side reactions occurs: as a consequence to the non‐specificity of plasma‐induced reactions and the sensitivity of the organic bonds, the chemical structure of monomers is only partially retained and the resulting PECVD layers, called plasma‐polymers, strongly differ from conventional polymers.

Numerous strategies have been developed to mitigate the negative impact of plasma and promote conventional polymerization pathways: the pulsing of the discharges has been widely investigated to temporally isolate plasmas. A research team from The Luxembourg Institute of Science and Technology investigated the mass spectra of thin films elaborated from methyl methacrylate (MMA) and GMA at two plasma pulse frequencies in an attempt to rigorously decode the various plasma mechanisms affecting the atmospheric‐pressure plasma‐initiated chemical vapor deposition (AP‐PiCVD) of poly(alkyl acrylates).

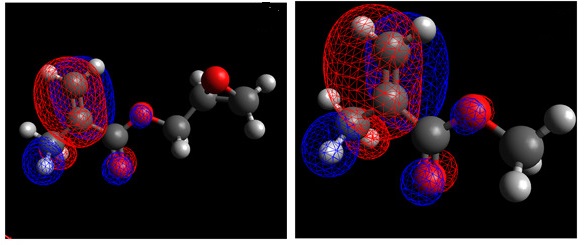

Using a unique σ‐bond breakdown per molecule as an initial hypothesis, the near integrality of the matrix‐assisted laser desorption/ionization high‐resolution mass (MALDI–HRMS) spectra was successfully addressed for the coating obtained at low frequency. As such the ability to strongly favor a conventional pathway using molecular functionalities opens new possibilities for the chemical engineering of molecules specifically designed for plasma‐polymerization. ” So combining an optimal chemistry with soft deposition processes such as the atmospheric pressure PiCVD may allow for the conventional growth of high molecular weight polymeric layers, with a extremely high chemistry retention using buffer functions” according to team member Nicolas Boscher.