Polymers such as polyisoprene and polybutadiene (the main components of natural and synthetic rubber) are abundant in most areas of modern life and, depending on their application, it is imperative to characterize properties such as molecular size, molar mass, chemical composition, microstructure and their respective distributions. However, because of the inherently complex nature of polymers, current separation techniques such as size exclusion chromatography (SEC) are not always suitable for comprehensive analyses. SEC is widely considered to be the workhorse for polymer characterization but has significant limitations in the analysis of very high molar mass compounds as shear degradation might occur due to interactions with the stationary phase and the column frits yielding potentially erroneous results.

Polymers such as polyisoprene and polybutadiene (the main components of natural and synthetic rubber) are abundant in most areas of modern life and, depending on their application, it is imperative to characterize properties such as molecular size, molar mass, chemical composition, microstructure and their respective distributions. However, because of the inherently complex nature of polymers, current separation techniques such as size exclusion chromatography (SEC) are not always suitable for comprehensive analyses. SEC is widely considered to be the workhorse for polymer characterization but has significant limitations in the analysis of very high molar mass compounds as shear degradation might occur due to interactions with the stationary phase and the column frits yielding potentially erroneous results.

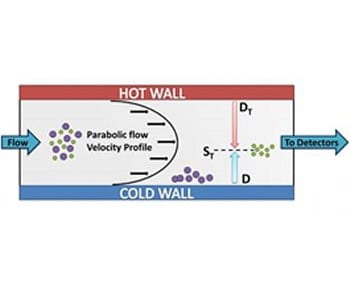

A powerful alternative to column-based chromatography methods, such as SEC, is thermal field-flow fractionation (ThFFF). ThFFF is a subtechnique of field-flow fractionation (FFF) that uses thermal diffusion to separate a large variety of polymers. ThFFF applies a temperature gradient perpendicular to a carrier liquid flowing through an open, ribbon-like channel and due to the absence of a stationary phase, ThFFF is well suited for analysis of high molar mass compounds, fragile complexes, highly branched polymers and various kinds of aggregates and colloids.

To date ThFFF has been shown to separate polymers according to size, chemical composition and architecture. H. Pasch and co-workers (University of Stellenbosch, South Africa) have now demonstrated the use of ThFFF as a novel tool for the microstructure separation of polyisoprene and polybutadiene. The 1,4- and 3,4-isomers of polyisoprene as well as the 1,2- and 1,4-isomers of polybutadiene were separated according to differences in microstructure. Characterisation of microstructure is important as it can have a profound effect on properties such as glass transition temperature, solubility, viscosity and durability of the polymer. Furthermore, the authors also demonstrated that carrier liquid structure and viscosity can have a dramatic influence on the separation mechanism in ThFFF with the more viscous solvent yielding better separation.

Polyisoprene and polybutadiene are important industrial polymers whose applications in new fields are limited by their lack of advanced characterisation methods, especially for polymers of very high molar masses. Demonstrating the capability of ThFFF to separate these polymers according to microstructure not only highlights the uniqueness of ThFFF’s separation mechanism but more importantly, opens the door to better characterisation of high molar mass polyisoprene and polybutadiene polymers in order to potentially extend their range of applications. This work is of great importance since it brings solutions to a very complex issue.