According to the German based company Siempelkamp, its resin blending system for medium-density fibreboards (MDF) not only reduces resin consumption considerably but also achieves a previously unattainable homogenous resin distribution. Due to special nozzle technology and the use of superheated steam, resin savings up to 20% compared to the traditional blending process in a blowline can be achieved.

An argument which is convincing to their customers, as the company told. Since its market introduction, 18 systems have already been sold. Siempelkamp supplies the novel blending system as ready-to-install complete blending system including switchgear cabinet and automation software.

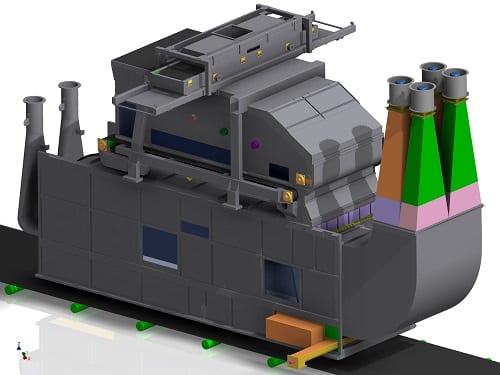

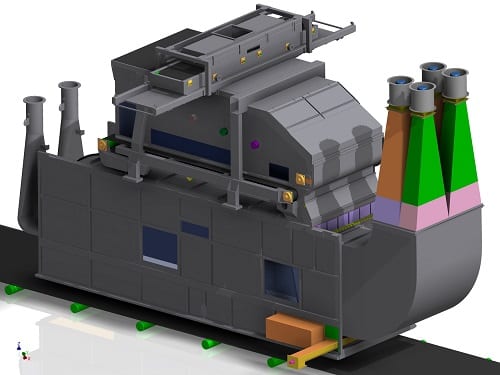

CMC Texpan, a Siempelkamp subsidiary and specialist for wood preparation, will present a new product for particleboard production at the fair Xylexpo 2014: a wind-forming technology, the so called HP WindFormer, offers uniform forming of the surface layer crosswise to the direction of production.

CMC Texpan, a Siempelkamp subsidiary and specialist for wood preparation, will present a new product for particleboard production at the fair Xylexpo 2014: a wind-forming technology, the so called HP WindFormer, offers uniform forming of the surface layer crosswise to the direction of production.

Perforated plates (diffusers) and a more uniform airflow provide for improved air distribution in both the vertical and horizontal directions. The new mat-forming process leads to the production of higher quality boards while using less material, as the machinery and plant manufacturer pledges. Furthermore, by reducing the blower capacity, additional energy savings can be obtained.

In the context of the fair, Siempelkamp reports about the further development of the proven press that offers plant operators advantages when it comes to material savings. With innovative pressure distribution plates and an additional row of cylinders, the press operates virtually isobaric and has become ten times more precise.

The improved pressure distribution combined with high availability, a feed rate/speed of up to 2,000 mm/s and the flexible infeed head make this generation the most advanced in the company’s portfolio. Pressure distribution plates, resin blending system and wind former are suited for installation in new plants and, if certain space conditions are met, for retrofitting.

More information about the woodworking technology fair Xylexpo 2014: http://www.xylexpo.com