Metal organic frameworks (MOFs) can now be microfabricated in two dimensions, bringing them a step closer to incorporation in commercial miniaturized devices, such as labs-on-a-chip or microfluidic devices.

MOFs are ultraporous crystalline functional materials that are promising for a wide range of technological applications, due to the breadth of chemical and physical properties from a variety of metal co-ordinate and organic linkers. The key to their application in smart devices is gaining the ability to control their precise location using versatile, inexpensive and rapid processes.

In a joint project from CSIRO in Melbourne Australia, TASC Laboratories in Trieste, Italy and Kyoto University, Japan, researchers have recently developed a generic patterning technique that combines UV-lithography with the hot-pressing of preformed MOF crystals.

In a joint project from CSIRO in Melbourne Australia, TASC Laboratories in Trieste, Italy and Kyoto University, Japan, researchers have recently developed a generic patterning technique that combines UV-lithography with the hot-pressing of preformed MOF crystals.

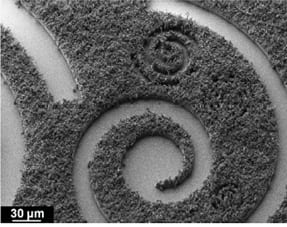

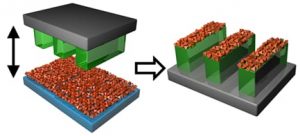

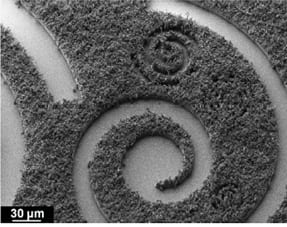

A standard UV lithography technique was used to pattern SU-8 resist on a silicon substrate. On a second substrate, MOF crystals were deposited by evaporation, dip-coating or spin coating of a MOF/solvent dispersion. The patterned SU-8 film was heated slightly above the glass transition of the resist (95°C) and was then pressed onto the MOF film. The MOF crystals were transferred and partially embedded into the SU-8 resist, resulting in a 2D patterned MOF surface. The patterning protocol was demonstrated with three different MOFs (an amino functionalised Al based MOF, NH2 -MIL-53(Al), and two imidazolate based MOFs, cobalt based ZIF-67 and zinc based ZIF-8).

The technique is very versatile due to the ability to pattern almost any type of preformed MOF. The resolution of the patterned MOF films is dependent on the size of the preformed MOF crystals.

To fur ther demonstrate the application of these patterned MOFs for potential sensing or biomedical devices, the incorporation of bioactive materials was achieved. Enzymes (β-glucosidase) were grafted onto the patterned NH2-MIL-53(Al) MOF. The MOFs maintained their chemical functionality and patterned structure, making them promising materials for bioprocessing applications. To prove that the MOFs maintain their accessible porosity, the patterned NH2-MIL-53(Al) MOF was impregnated with Pd. The same amount of Pd was taken up from an equivalent amount of loose powdered MOFs compared with the patterned MOFs.

ther demonstrate the application of these patterned MOFs for potential sensing or biomedical devices, the incorporation of bioactive materials was achieved. Enzymes (β-glucosidase) were grafted onto the patterned NH2-MIL-53(Al) MOF. The MOFs maintained their chemical functionality and patterned structure, making them promising materials for bioprocessing applications. To prove that the MOFs maintain their accessible porosity, the patterned NH2-MIL-53(Al) MOF was impregnated with Pd. The same amount of Pd was taken up from an equivalent amount of loose powdered MOFs compared with the patterned MOFs.

This straightforward, adaptable and effective technique is suitable for the patterning of almost all metal-organic frameworks as the imprinting technique is independent from the lithography process. The chosen resist can also be deposited and patterned on different substrates (paper, plastic). This innovative technique offers the potential of incorporating MOFs in miniaturised devices on a commercial scale.