Ventilators have been one of the mainstays of combatting lung infections due to COVID-19. However, their enormously high cost (up to $50,000 USD) precludes a hospital’s ability to stockpile them for emergencies, such as the current global pandemic. This problem is far worse in the poorer countries, the magnitude of which was underscored in a recent New York Times article, in which ten African countries were found to have no ventilators at all.

The COVID‐19 pandemic has brought to light the need for simpler, readily-available devices that can address the urgency and impact of the situation rather than only relying on high‐end, all‐rounded “perfect” devices.

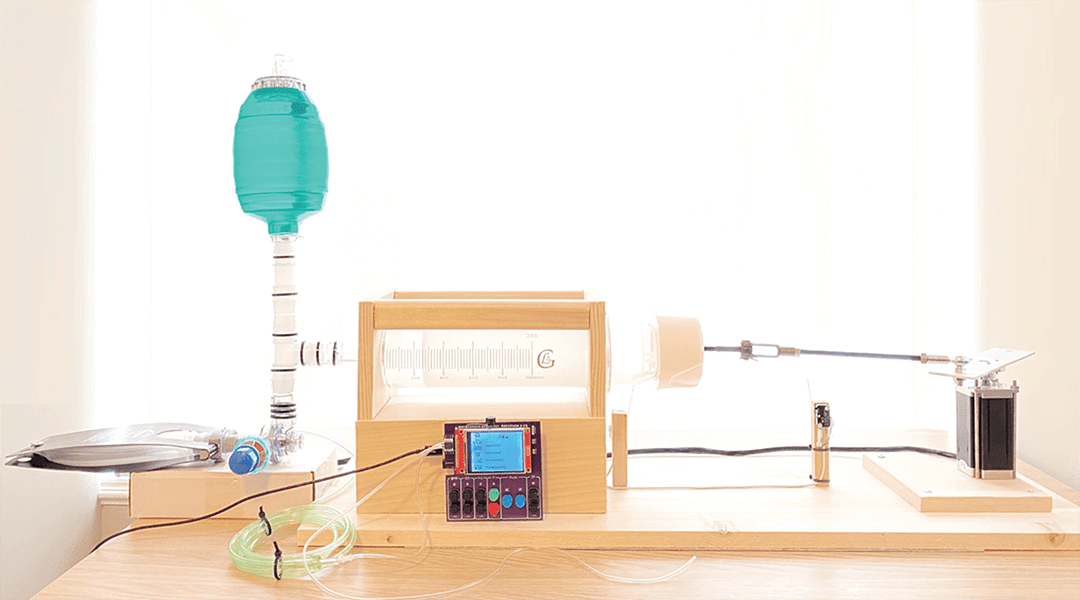

In a study published in the journal Advanced Intelligent Systems, a portable, low-cost, and high-performance ventilator called IPAM (inverse pneumatic artificial muscle) ventilator was developed. The device is built from commercially available parts that cost on the order of $250 USD.

It uses a digitally controlled stepper motor connected to an air cylinder to generate a precise volume and pressure of air for mechanical ventilation. It possesses only the essential features, such as the safety features, and the two most common modes of operation; this fundamental design can address the demand for ventilators in life‐death situations.

The current design rationale is based on optimizing the performance (e.g., accuracy, portability, and cycle life), simplicity, time to manufacture, scalability, and cost while utilizing generic and readily available components. Custom-made parts (e.g., 3D printed components, machined gears, and injection‐molded pieces) were avoided and off‐the‐shelf components were used to cut down the cost further.

The device could possibly act as a substitute for high‐end medical grade ventilators or could be part of first aid or medical kits in large companies or institutions, such as universities and airports. Moreover the IPAM ventilator could be used as an education and training tool or, considering the precision that was achieved, the IPAM ventilator can possibly be used as an anesthesia ventilator as well.

The next challenges include obtaining certifications, productizing the design for manufacturing, and introducing it to the medical channels for exposure and availability. In the current case of the public health emergency, governmental health organizations, such as Health Canada and the FDA, have relaxed the mechanical ventilators’ approval process. However, the device still has to be manufactured according to FDA requirements.

Although these challenges have yet to be solved, there is optimism that this device can lower the barrier for procuring the ventilator, especially in under-developed countries, for use in emergencies such as this.

Reference: Seyed M. Mirvakili, Douglas Sim, Robert Langer, et al. Inverse Pneumatic Artificial Muscles for Application in Low‐Cost Ventilators. Advanced Intelligent Systems (2020). DOI: 10.1002/aisy.202000200

The article was amended on November 20, 2020