Open celled metal foams have a wide variety of possible applications including heat exchangers, energy absorption, flow diffusion and lightweight optics. Due to the high cost of the material it is most typically used in advanced technology like aerospace applications.

To evaluate the behavior of porous materials like these X-ray tomography is widely used. With this method, a three dimensional volume can be inspected to visualize in situ the progress of damage in materials. X-ray computed tomography (XRCT) has appeared recently to be a very powerful tool allowing to characterize the microstructure of cellular materials. The resolution available using the laboratory-based version of XRCT (LXRCT) is more than sufficient to visualize the cellular microstructure of cellular materials.

Unfortunately, under these conditions of medium resolution, the actual microstructure of the solid metal cannot be resolved. However, several studies on aluminum-based metal open cell foams revealed that inter-metallics play a key role at the local scale on the fracture process.

Recently, a group of French and Dutch researchers used LXCRT images of open cell aluminum foam at two different scales during an in situ tensile test. They analyzed the global fracture process and also the effect of the microstructure of the metal inside, the struts on the local fracture process.

Recently, a group of French and Dutch researchers used LXCRT images of open cell aluminum foam at two different scales during an in situ tensile test. They analyzed the global fracture process and also the effect of the microstructure of the metal inside, the struts on the local fracture process.

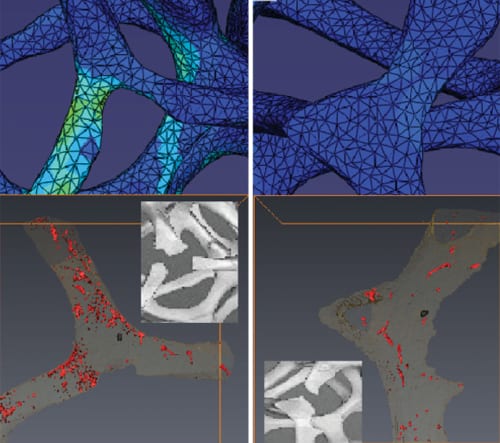

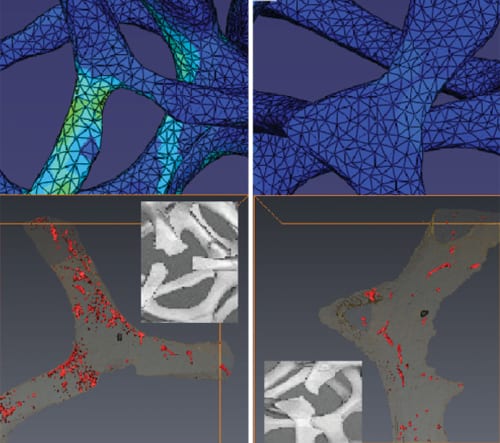

First, they studied the internal structure of the foam by high resolution local tomography which led to detailed information about the location of inter-metallics. The fracture process of the material during tension was then captured using low resolution scans during a high number of deformation steps of the foam.

The low resolution scan in the initial state was also used as input for an image-based FE calculation leading to the detection of regions where the stresses are high in the material. In the fracture zone, some of the broken struts were highly loaded while some others where much less loaded. The results of the experiments revealed that the local microstructure plays a key role in the initiation of fracture.

The researchers considered this method as very helpful to optimize the rupture properties of these materials as a predictive tool. It reveals all necessary information about local concentrations of defects as well as their effect on the fracture strain and determines the local stress using the FE model.