Replacing conventional construction materials with lower-density materials such as the light metals aluminum, magnesium, and their alloys, requires the appropriate production technology. Amongst others, joining and particularly detachable joining of light metals is a great challenge.

The use of traditional steel screws for joining light metal structures has considerable disadvantages: the low conformity of the coefficient of thermal expansion and Young’s modulus leads to a significant loss of clamp force and galvanic corrosion emerges due to significant differences in the corrosion potentials of steel and aluminum or steel and magnesium.

The use of traditional steel screws for joining light metal structures has considerable disadvantages: the low conformity of the coefficient of thermal expansion and Young’s modulus leads to a significant loss of clamp force and galvanic corrosion emerges due to significant differences in the corrosion potentials of steel and aluminum or steel and magnesium.

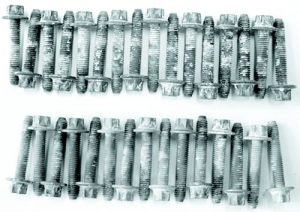

The application of self-tapping screws made of aluminum is a promising technology for light-metal joining. The disadvantages are overcome by substituting steel as joining element material and joining the parts without previous thread-cutting saves efforts and a significant amount of time in the manufacturing process.

In this field, stringent requirements regarding the wear resistance of screw surfaces result from the thread-forming process. Researchers from the Chemnitz University of Technology, Germany, and the industrial fasteners division of the company EJOT have examined the influence of hard anodized layers on the screwing behavior and susceptibility to stress corrosion cracking of high-strength aluminum screws. Both requirements have to be met to facilitate application of the technology for industrial-scale joining not only of plastics or light-metal alloys with low strength, but also for joining high-strength lightweight alloys.

Test results of the screwing and thread-forming behavior substantiated the necessity of hard anodizing treatment. Without previous hard anodizing, specimens failed in the thread-forming process because of cracking due to high torque. The hard anodized screws showed much better thread-forming and screwing behavior. Due to the lower required torque, none of the hard anodized specimens cracked. In combination with the obtained results in terms of susceptibility to stress corrosion cracking, hard anodizing proves to be the surface modification of choice. The influence of the oxide coating on fatigue behavior of the screws will be examined in future work.