Many years of research and development have been employed to improve the performance of orthopedic implant materials. While these efforts have seen tremendous advances in the ability of these materials to integrate with bone, the long-term success of orthopedic implants crossing the skin, such as lower limb prostheses, has been hampered by an inability of some of these devices to maintain a stable seal with the surrounding skin tissue. Such a failure allows opportunistic environmental bacteria to colonize the space between the implant and the skin.

Many years of research and development have been employed to improve the performance of orthopedic implant materials. While these efforts have seen tremendous advances in the ability of these materials to integrate with bone, the long-term success of orthopedic implants crossing the skin, such as lower limb prostheses, has been hampered by an inability of some of these devices to maintain a stable seal with the surrounding skin tissue. Such a failure allows opportunistic environmental bacteria to colonize the space between the implant and the skin.

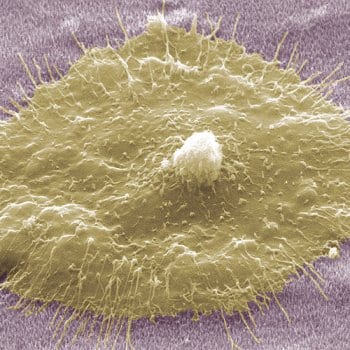

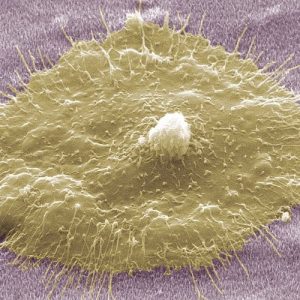

In new research, Park and colleagues describe a method for imparting a new type of topographical structure to titanium, the most common of orthopedic implant materials. This structure, consisting of micro-scale and nano-scale features, not only maintains the ability to promote the formation of bone cells from stem cells, but also supports the attachment of skin cells, while resisting bacterial growth.

The surface treatment was originally designed for lower limb, integrated prostheses but also has application to knee and hip replacements, where soft tissue integration and improved biofilm resistance has been an unmet need for many years. The treatment has immediate application in the field of dental prostheses, which in terms of numbers, are much more widely applied. Finally the possibility of applying a similar surface treatment to other materials and implants such as long-term, indwelling catheters and sensors promises to significantly improve the reliability of these devices and improve the quality of life for, heart patients receiving continuous drug infusions, for cancer sufferers, and for diabetics.