However, in real-world applications, because the incident angle of solar irradiation changes over time during daytime, flat solar panels, even those integrated with state-of-the-art light harvesting structures, are inadequate in energy retaining especially when the incident light angle increases. This limitation inspired Dongdong Li and co-workers at Shanghai Advanced Research Institute, China Academy of Science, along with collaborators Hanzhong Zhang at Changzhou 3D Solar Technology Ltd., and Xufei Zhu at Nanjing University of Science and Technology (all in China), to design an omnidirectional thin-film amorphous silicon (a-Si:H) solar cell module through 3-dimensional geometry engineering.

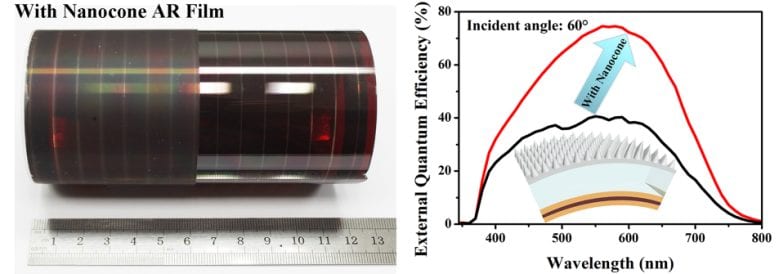

The novelty in their design is two-fold: they deposit functional layers onto the inner surface of macroscopic tubular glass substrates, and at the same time introduce nanoscale cone-shaped AR coating. While the top and bottom transparent boron doped zinc oxide electrolyte layers are grown by low pressure chemical vapor deposition, the middle stack layers of a-Si:H silicon are fabricated by a homemade plasma enhanced chemical vapor deposition system. Thanks to the unique tubular structure, the device can be easily encapsulated by capping the ends of the glass tube, thus avoiding expensive lamination methods.

In this tubular cell scheme, despite the absence of back reflectors, the unabsorbed light can pass through the tubes and eventually be absorbed by the solar cell directly or after multiple reflection within the tubes. The 3D tubular geometry can effectively collect sunlight in a broad range of incident angles, where the variation in the incident angle of sunlight is minimized. On the other hand, flexible polymer AR films featuring 3D nanocone arrays can further improve the sunlight collection under the large oblique incident angles, which has been a challenge for the smooth glass surface. In addition, the highly hydrophobic AR films are capable of self-cleaning, an advantage much desirable in large-scale deployment.

With excellent light collection capability, the tubular solar cell module reaches a PCE of 9.12% under one sun illumination, which is further increased to 9.86% when equipped with nanocone-structured AR films. Compared to traditional flat panels, this new design, while reaching high efficiency, significantly reduces the material consumption and solar panel installation cost, providing a practical solution for large-scale photovoltaic application.