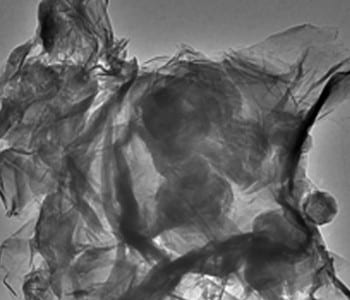

A TEM image of the GO-S composite material.

Chinese researchers have developed a graphene-based composite material to improve the performance of lithium-sulfur batteries. Their “leaf-like” graphene oxide nanostructures, with a carbon nanotube rib, dramatically improve the cycling performance and stability of test systems.

Although lithium-sulfur batteries have started to attract a great deal of research attention – in part as their specific capacity is a major improve over the much more common lithium-ion –several problems in the nature of sulfur and its reaction products means that they’re not yet the final product. Dissolution in liquid electrolytes, large volume expansions, and a general insulating nature make sulfur a difficult material to integrate into a fully functional, useful battery.

By synthesising leaf-shaped graphene oxide materials, with a highly conductive carbon rib support, a team working from Fudan University have overcome many of these problems. When these graphene oxide leaves were used to prepare GO/sulfur cathodes, the group could produce 85wt% sulfur batteries with promising cycling performance, and found capacity decay of just 0.033% over 1000 cycles when using 60wt% sulfur.

By wrapping the sulfur cathodes in this graphene material, the composite material combines the advantages from graphene oxide, carbon nanotubes, and sulfur, and although many challenges remain before anyone can claim a successful lithium-sulfur battery, this research will stand as a jumping-off point for the next step.