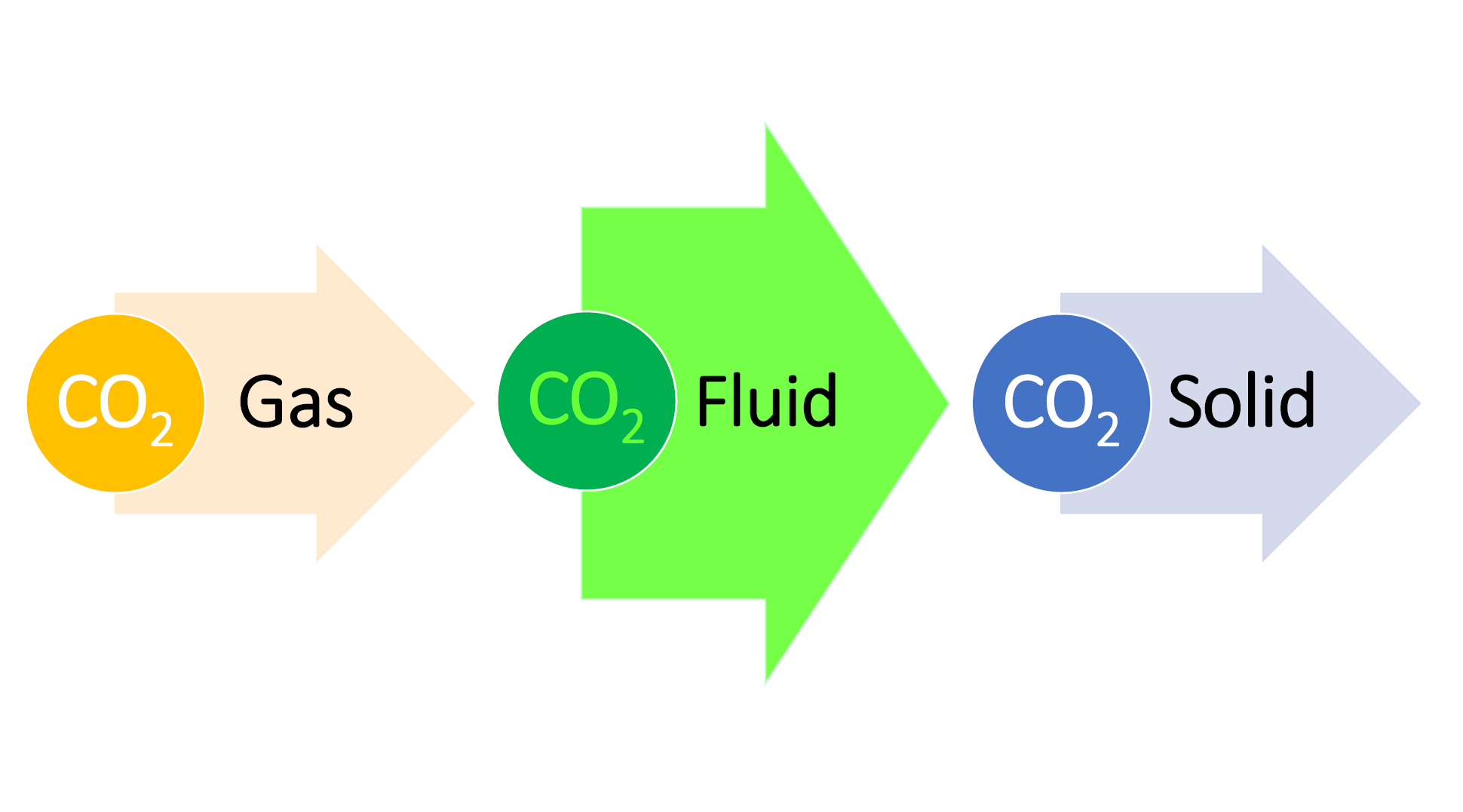

At standard temperature and pressure, CO2 exists as a gas. On cooling to -78.5°C, it becomes a solid called dry ice, which is a common refrigerant. At a critical temperature and pressure of 31.1°C and 72.9 atmospheres, respectively, CO2 becomes a supercritical fluid with properties intermediate to a gas and liquid. In this form, CO2 fills a containment vessel and exhibits a low viscosity reminiscent of a gas but retains the high density of a liquid.

It is this favorable combination of gas- and liquid-like properties that has brought favor to supercritical CO2 as an abundant, cheap, easy to handle, low toxicity, and environmentally benign, multipurpose solvent for many commercial and industrial processes. These include coffee decaffeination, cannabis extraction, pesticide removal from crops, dry cleaning, strengthening cement, enhanced oil recovery, and foaming polymers.

It turns out that supercritical CO2 also has rather appealing properties as both solvent and reagent in the electrochemical reduction of CO2 to a variety of products; a process normally carried out in aqueous solution under ambient conditions.

The idea behind this approach to CO2 reduction is that problems encountered in aqueous electrochemistry, such as those associated with the low solubility of CO2 in H2O, mass transport of solutes to electrode surface, separation of reactants and products, competing H2 evolution, low product selectivity, high over-potentials and low current densities, could potentially be overcome by working with supercritical CO2.

In practice, however, for a viable supercritical CO2 electrochemistry process, besides the added complexity of operating in pressurized reactors, H2O is required to provide protons for making products such as methanol or formic acid. Furthermore, electrolytes, neutral, acidic and basic solutions, co-solvents, and organics are needed to afford control over ionic conductivity, pH, solubility, and the dielectric constant of supercritical CO2.

Even though the possibility of electrochemical reduction of CO2 in supercritical CO2 can be traced back to the late 1980’s, activity in the field has remained in its infancy and it’s still early days in research and development aimed at defining the scientific potential of this innovative endeavor.

Meanwhile, from the few ongoing studies, certain advantages of working in supercritical CO2 are becoming apparent, such as the ability to subdue the evolution of H2, and tailor product selectivity through the above mentioned additives.

Technical challenges nevertheless remain before the electrochemistry in supercritical CO2 can become a practical technology. These include electrode corrosion, unwanted product oxidation, deleterious carbon deposition, and improvements in product selectivity.

While progress has been slow towards evaluating the true potential of supercritical CO2 as a ‘green’ solvent for electrochemical reduction of CO2 to a variety of products, research and development in the area are anticipated to gain momentum as interest in CO2 utilization for helping to ameliorate climate change is rapidly growing.

Written by:

Geoffrey Ozin

Solar Fuels Group, University of Toronto, Toronto, Ontario, Canada, Email: [email protected], Web sites: www.nanowizard.info, www.solarfuels.utoronto.ca, www.artnanoinnovations.com.