The community of scientists and engineers enamored with the conversion of CO2 to renewable synthetic fuels are for the most part, dedicated to the discovery, development, scaling, and stability of materials and reactors for facilitating these reactions, whether it be using heat, electricity, or light. Ultimately, most of these researchers work on devising strategies to yield the most energy efficient and cost-effective CO2 conversion technologies.

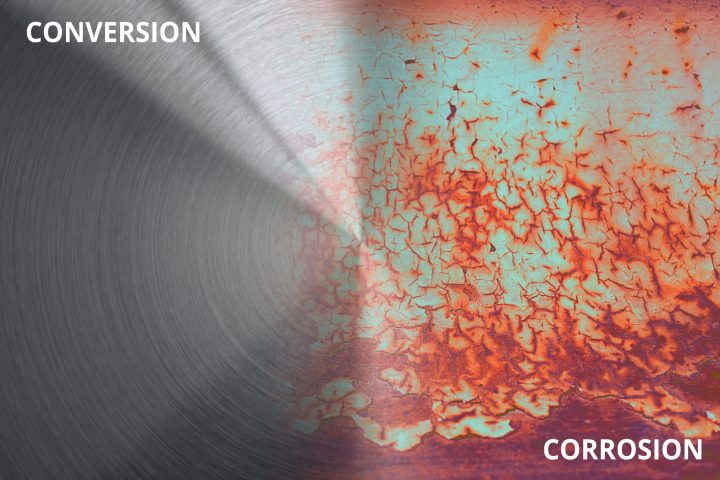

Two faces of steel – scientists and engineers working on carbon dioxide conversion through stainless steel pipelines and reactors might not be thinking about the other side of the problem, corrosion of these reactors and pipelines by carbon dioxide, and vice versa. Graphic illustration courtesy of Chenxi Qian.

There exists, however, another community of scientists and engineers, captivated with the capture, purification, transportation and distribution of CO2 for either storage or enhanced oil recovery purposes. Their attention is largely focused on the important, and yet often forgotten corrosive nature of CO2 on processing equipment, containers, and pipelines made of carbon steel, under a range of operating conditions (e.g., temperature, pressure, flow, and trace impurities such as H2O, H2S, O2, NOx and SO2). These types of CO2 corrosion problems are also ubiquitous in oil and gas pipelines where impurity gases are present in the hydrocarbon fluid. The overarching goal of these endeavors is to understand how CO2 surface chemistry and electrochemistry in the presence of these impurities affects the stability, reliability, useable lifetime, economics and safety of the system.

Do practitioners in these two fields know of the existence of one another? Are they aware of the challenges each face solving their respective problems? Both have to handle CO2 to achieve their goals and both need to understand the chemistry and reactivity of CO2 under a range of conditions.

To amplify, the conversion of CO2 to synthetic fuels requires an understanding of its chemical reduction under gas-phase and aqueous-phase conditions to fuels such as CO, CH4 and CH3OH, driven by heat, electricity, or light. Scientists and engineers working on this problem have to be duly cognizant of the reactivity, stability, and safety of steel (or whatever alloy) equipment towards reactants and products in these CO2 conversions in the presence of H2O as a product or solvent.

In the case of capture, transport, storage of CO2, carbon steel in contact with rigorously dry CO2 does not corrode; however, it does in the presence of carbonic acid, H2CO3, formed from CO2 and H2O. The corrosion mechanism and the nature of the resultant film depends sensitively on the amount of H2O, pH, temperature and pressure, and can occur through chemical and electrochemical pathways.

For example, iron carbonate surface films, which grow from Fe-CO2-H2O, can be either insoluble and protective or soluble and non-protective. This will depend on the thickness, coverage and texture of the films and surrounding conditions, gaseous or fluid, oxidative or reductive, acidic or basic, static or dynamic.

Similar ideas apply to SO2-H2SO3-FeSO3, H2S-FeS and O2-Fe2O3-Fe3O4 systems and the corrosion chemistry and electrochemistry. If the surface film so formed provides insufficient protection, local and rapid corrosion can play havoc with steel containers, equipment, and pipelines used in the CO2 capture and utilization, oil and gas industries.

Interest in both CO2 capture, storage, and utilization technologies, and CO2 in the oil and gas industries is rapidly growing. Given the current trend, these seemingly disparate fields would greatly benefit by overcoming the CO2 communications gap, which appears to exist between scientists and engineers working on these problems.

Written by:

Geoffrey A Ozin

Materials Chemistry Research Group, University of Toronto, Toronto, Ontario, Canada, Email:[email protected], Websites: www.nanowizard.info, www.solarfuels.utoronto.ca, www.artnanoinnovations.com