Prolonged release of antibacterial agents can be useful to keep pathogens under control for long periods of time. There is high industrial interest in paper as a material to functionalize in order to generate value-added products, and applications in the medical field clearly have these characteristics.

Prolonged release of antibacterial agents can be useful to keep pathogens under control for long periods of time. There is high industrial interest in paper as a material to functionalize in order to generate value-added products, and applications in the medical field clearly have these characteristics.

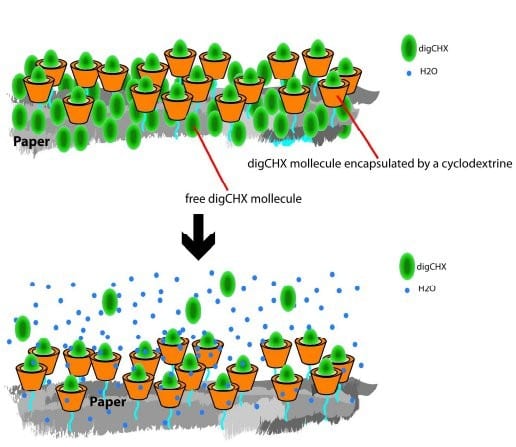

One way to add functionalities to paper for incorporation of biologically active ingredients is using beta-cyclodextrins, large circular molecules made by enzymatic degradation of starch, and basically consisting of a number of sugar molecules strung together in a circle. The cavity within the circle is relatively hydrophobic, and thus can be used to entrap lipophilic molecules (as several drugs are) through host-guest interactions.

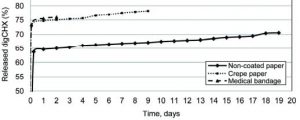

Although paper functionalization with cyclodextrins has been looked at already, adding value to a product like paper for packaging and medical uses passes through a series of optimizations, and finding some key property that makes the material really useful. This is exactly what Oriol Cusola and colleagues in Grenoble, Barcelona and Lille have done, in a new paper published in the Journal of Applied Polymer Science, by functionalizing different types of paper (a non-coated paper , a 100% cotton based medical bandage, and a medical crepe paper), and experimenting with different types of linkage of the cyclodextrin to the paper substrate.

The authors discovered that, when they used citric acid to crosslink the cyclodextrin to the substrate, they could obtain release of the antiseptic agent chlorhexidine digluconate over extremely long periods of time. After an initial burst release, the drug continues to leach out of the antibacterial paper for twenty days in small quantities. Such small amounts could still be useful in the treatment of some skin or teeth pathogens, without the need to reapply the antiseptic material. The prolonged release is not seen instead without the crosslinking agent. On the other hand, optimally crosslinked samples also did not provide long-term release, perhaps due to the entrapment of the drug within the 3D network of bonds generated by the prolonged crosslinking.

The authors discovered that, when they used citric acid to crosslink the cyclodextrin to the substrate, they could obtain release of the antiseptic agent chlorhexidine digluconate over extremely long periods of time. After an initial burst release, the drug continues to leach out of the antibacterial paper for twenty days in small quantities. Such small amounts could still be useful in the treatment of some skin or teeth pathogens, without the need to reapply the antiseptic material. The prolonged release is not seen instead without the crosslinking agent. On the other hand, optimally crosslinked samples also did not provide long-term release, perhaps due to the entrapment of the drug within the 3D network of bonds generated by the prolonged crosslinking.

Since the paper manufacturing process is not affected by the functionalization (the authors use various types of commercial papers as substrates) the process has a good potential to be a practical way to add value to paper products. However, the authors caution about the fact that this is only a first study, and further verification of the papers’ antiseptic effects have to be performed in future studies.