Transition metal oxides (TMOs) have been proposed as promising anode materials for next-generation high-energy lithium-ion batteries (LIBs). However, the terrible decay in capacity over time in this systems still seriously hinders their application. This capacity loss is mainly due to the inevitable pulverization and cracking of the TMOs, due to the drastic volume changes that the system experiences during the lithium uptake and release processes, and that the commercial PVDF binder used in LIB electrolytes swells easily.

Transition metal oxides (TMOs) have been proposed as promising anode materials for next-generation high-energy lithium-ion batteries (LIBs). However, the terrible decay in capacity over time in this systems still seriously hinders their application. This capacity loss is mainly due to the inevitable pulverization and cracking of the TMOs, due to the drastic volume changes that the system experiences during the lithium uptake and release processes, and that the commercial PVDF binder used in LIB electrolytes swells easily.

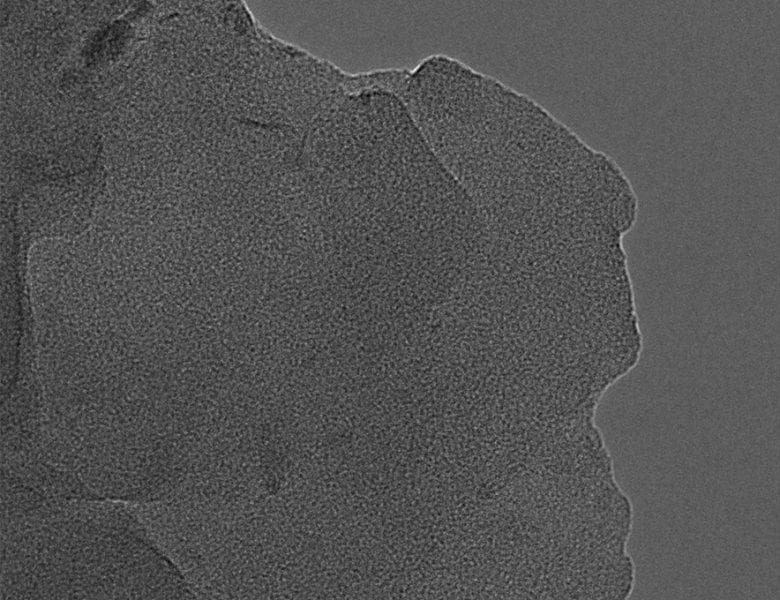

To meet these daunting challenges, using binder-free TMOs nanosheet/graphene electrodes could theoretically improve both power and energy density. However, this proposal requires the fabrication of uniform, full, and tight TMOs nanosheet coatings on graphene, and such a coating remains very challenging to successfully make.

Now, Xin-Bo Zhang and co-workers at CAS and Beihang University have reported a process to create a homogeneous coating of CoO on graphene using a novel electrostatic-induced spread growth method, which they then used to fabricate binder-free and mechanically robust CoO/graphene electrode. These electrodes exhibit high rate capability and excellent cycle stability up to 5000 cycles, and their preparation method opens up a promising strategy to develop high performance anode for next-generation LIBs. It could also be extended to other TMOs/graphene hybrids, which can be used in other fields such as electrochemical capacitors and sensors.