A new sealant meant to mimic lung tissue has been shown to rapidly cork air leaks following surgery. Moreover, the protein-like molecules within the sealant were found to potentially help with wound repair.

“Our lung-mimetic sealant is designed with a structure similar to that of the healthy lung, allowing the sealant to deform in a similar way as the breathing lung,” explained Meghan Pinezich, researcher at Columbia University in the US, and first author on the study, in an email.

Nearly 60% of people experience an air leak following lung surgery. “An air leak is like having a flat tire in your lung — your lungs cannot inflate, a situation that is extremely dangerous and painful,” said Gordana Vunjak-Novakovic, another of the study’s authors and researcher at Columbia.

Common though it might be, the complication can have severe consequences, such as a lengthened hospital stay and even risk of death. While currently available surgical sealants are often used to plug these holes, the repeated expansion and contraction of the lungs can make them ineffective.

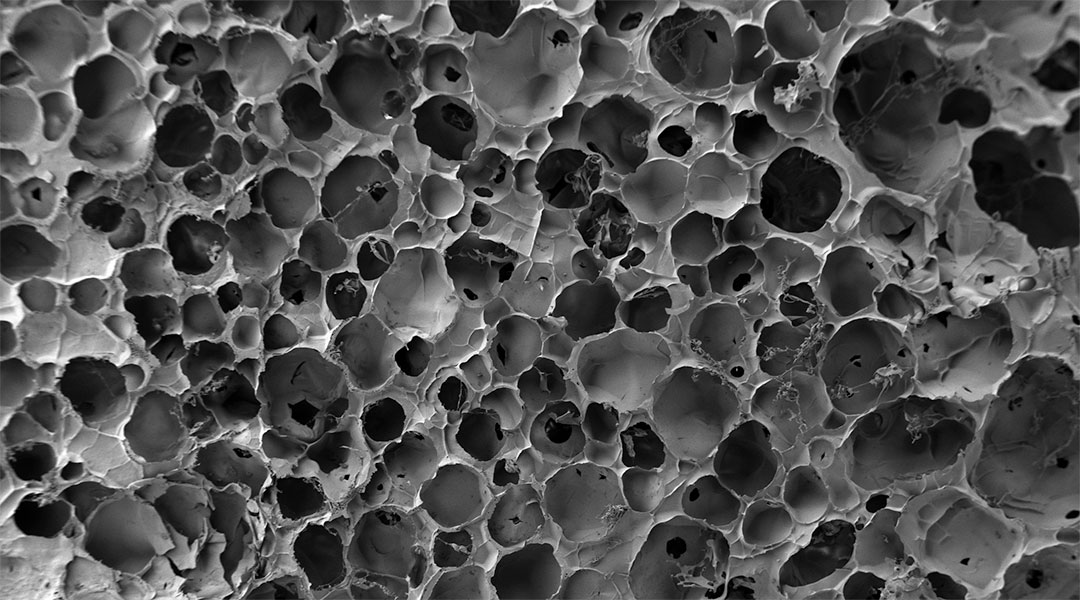

With a team comprising surgeons and engineers, the researchers attempted to craft a superior sealant, one that would mimic the structural and mechanical properties of lung tissue. To achieve this, the sealant was made from a porous material inspired by the structure of the lungs.

Inspired by the lung

Through a series of tests, the researchers identified a sealant formulation with the best structural and functional properties. They also analyzed its toxicity to human cells and its ability to cause an immune reaction. In addition to these features, the novel sealant was also embedded with matrikines — small, protein-like molecules known to promote wound repair and healing in lung cells.

“The lung proteins [matrikines] added promoted cellular healing in vitro, a feature not offered by any existing sealant,” said Jinho Kim at the Stevens Institute of Technology in the US.

Once they had established that the sealant was safe and lung-like in structure and form, the team sought to test its efficacy in two animal models. First, they tested the sealant in a post-mortem rat model of air leak in the lungs. When the sealant was used to block a leak, it stuck fast to the tissue and helped repair it.

Next, the team assessed the sealant’s effectiveness in swine lungs, outside the body, in a model of pulmonary air leak. According to Vunjak-Novakovic, they chose to use swine lungs for its similarities to human lungs, in terms of “size, anatomy and breathing behavior.”

As the surgical site was continually dilating and constricting, the researchers found attaching the sealant a challenging task. But with the help of their surgical colleagues, they created a working protocol for delivering the sealant. Within 60 seconds of applying the sealant, they made note of its quick adherence to the surrounding lung tissue.

The road ahead

In the future, the team would like to further test the sealant in living models, compare it to the current surgical standard, and better understand the healing properties of the matrikines in the long term.

At present, there is but one approved sealant to stop pulmonary leaks. “The availability of a reliable lung sealant could allow patients to be discharged early, saving on cost, and reducing the risk of further complications,” added Kim.

Beyond these benefits, the researchers suggest that the mimetic sealant could hold more universal appeal for surgically tackling other biological leaks.

“The concept of ‘lung-mimicry’ in designing a therapeutic sealant may be extended to create other organ-specific surgical adhesives and sealants, including for blood vessels, skin, and intestine,” Vunjak-Novakovic added.

Reference: Meghan R. Pinezich, et al., Lung-Mimetic Hydrofoam Sealant to Treat Pulmonary Air Leak, Advanced Healthcare Materials (2024). DOI: 10.1002/adhm.202303026