In their work aimed at controlling the surface wettability of engineering materials, Huizhang Guo, Ingo Burgert and colleagues from ETH Zurich and Empa in Switzerland have developed both superhydrophobic and omniphobic wooden surfaces, which are useful for self-cleaning wood surfaces, or in anti-biofouling and drag reduction applications respectively.

Superhydrophobic surfaces show non-wettability and self-cleaning properties when in contact with polar and aqueous high surface tension liquids – known as the Lotus effect. Omniphobic surfaces repel liquids independent of their surface tension and thus work for water and oil. Omniphobic surfaces also occur in nature: the springtail cuticle, for instance, and this is from where the inspiration for the current work comes. By mimicking these natural surface structures, considerable control of the surface properties of the wood can be achieved.

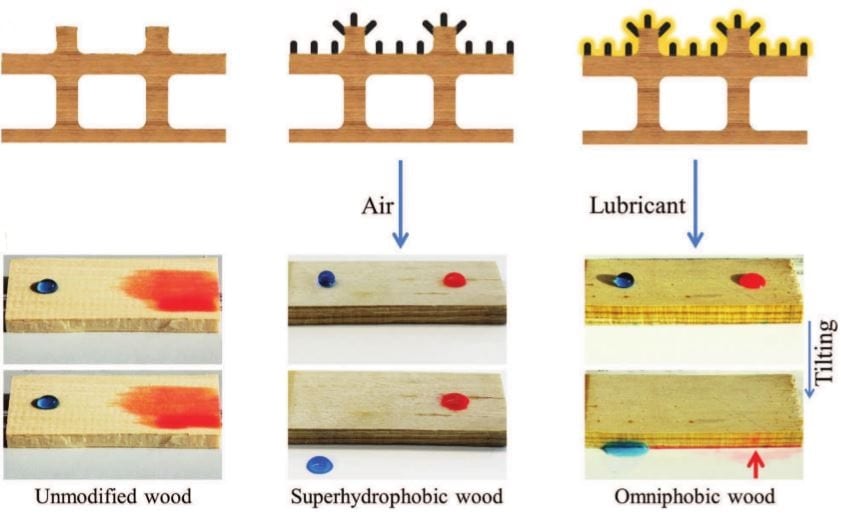

The image shows the effects of the ZnO particle coating (black) with or without the fluorinated lubricant (yellow) on how slippery the wood surface is towards water (blue) or oil (red) when the surface is tilted. A wide variety of applications can be imagined, from biomedical materials to shipping.

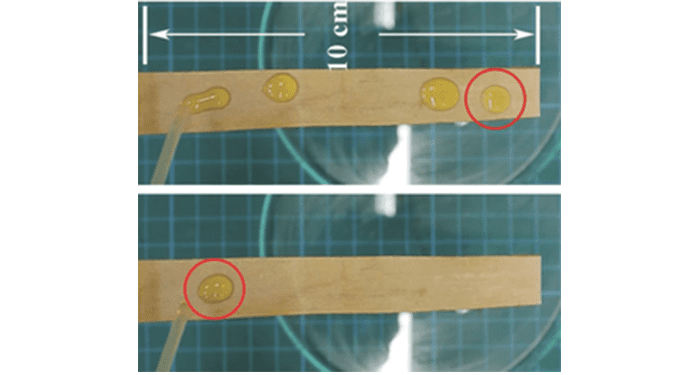

The group describe in their article in Advanced Materials Interfaces how they modify the surface of wood with a solution-based surface seeding technique followed by morphology controllable growth of ZnO crystals on the surface. Then, the superhydrophobic wood surfaces are generated by adding a coating of a fluorinated organic silane, and if the nanostructured wood surface is infused with a perfluorinated lubricant then omniphobic wood surfaces are produced, which repel both water- and oil-based liquids.