As a source of clean energy, solar cells have great potential to dominate future energy markets. Solar energy currently only accounts for a very small percentage of electricity used globally, but solar cells can be integrated relatively easily into infrastructure and commercial products. Emerging solar technologies are printable and have other advantages, but realizing their large-scale, global potential is limited by their power conversion efficiency (PCE) and operating stability.

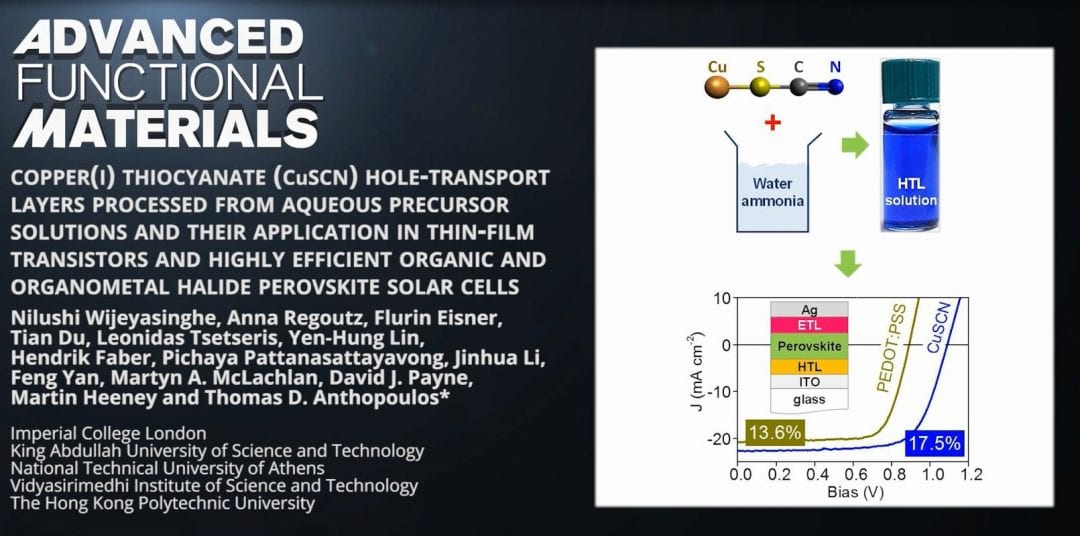

In a recent paper in Advanced Functional Materials, Professor Thomas Anthopoulos of the KAUST Solar Centre at King Abdullah University of Science and Technology in Saudi Arabia and the Centre for Plastic Electronics at Imperial College London, along with his colleagues, report a simple, inexpensive, and environmentally-friendly processing method for copper(I) thiocyanate (CuSCN), a next-generation interlayer material for solar cells.

When CuSCN is deposited as a thin film between the anode and light absorbing layer, it acts as a hole-transport layer (HTL) that significantly enhances the performance of both organic and hybrid perovskite solar cells. Compared to CuSCN layers processed using conventional sulfur-based solvents such as diethyl sulfide (DES), the layers processed in a mixture of water and ammonia have a remarkably smooth surface with no evidence of pinholes.

Organic photovoltaic devices based on the aqueous-processed CuSCN HTL yield a PCE of 10.7%, which is a significant improvement compared to 9.2% for devices with the DES-processed HTL and 9.7% for devices with a conventional polymer HTL. Hybrid perovskite solar cells with the aqueous-processed CuSCN HTL incorporated demonstrate an even higher PCE—a remarkable 17.5%, while similar cells containing a conventional polymer HTL only achieve a PCE of 13.6%.

After simulated solar illumination for 1 hour, the PCE of the perovskite solar cell with an aqueous-processed CuSCN HTL decreased to only 99.5% of its initial PCE, and then to 91.1% after an additional 2 hours. For organic solar cells, the CuSCN film strongly absorbs UV radiation and acts as a protective shield against degradation of the organic molecules. Conventional polymer HTLs lack this ability and the organic solar cells suffer from rapid performance degradation—a 35% drop in PCE occurs after only 10 minutes of illumination compared to only 15% when the CuSCN HTL is used.

To learn more about this promising new development for solar cells, please visit the Advanced Functional Materials homepage.