Carbon, originating from sources including coal and biomass, continues to be the dominant fuel source for power generation. However, the environmental impact of carbon dioxide emissions remains an issue. Direct carbon fuel cells (DCFCs) offer a means to increase energy conversion efficiency and thus reduce the environmental impact.

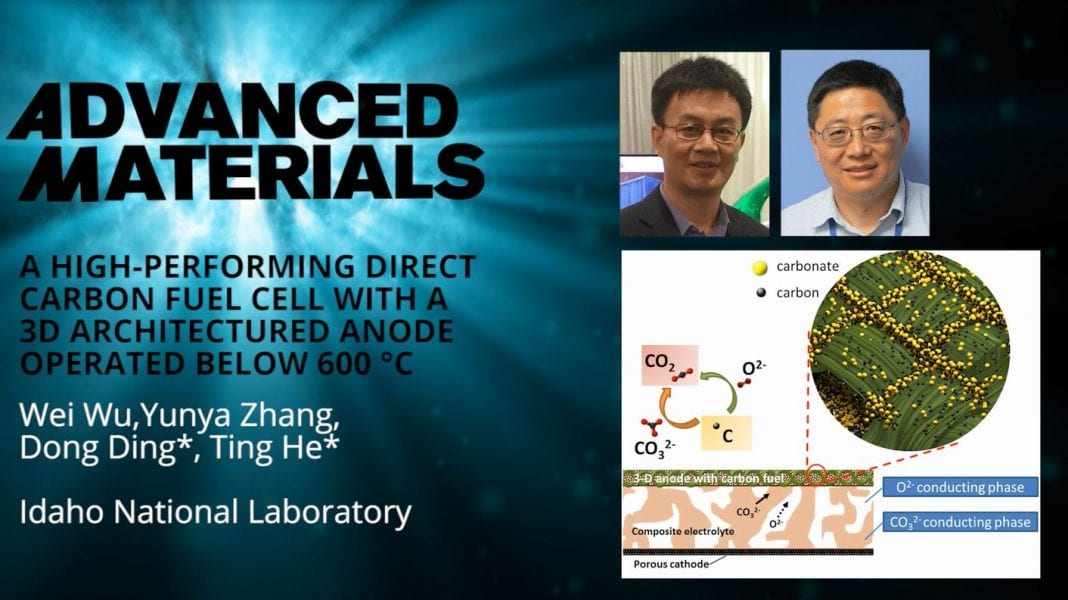

In their communication in Advanced Materials, Dong Ding, Ting He, and co-workers from Idaho National Laboratory fabricate an ultraporous ceramic framework with 3D architecture as an anode for high-performance DCFCs below 600 °C.

A fabric textile coupon was immersed in a solution of highly conductive cerium-gadolinium oxide compound (GDC) and Ni precursor, and then fired to form a nickel oxide–GDC ceramic textile. The ceramic textile was punched to size and then bonded on the top of a GDC-carbonate electrolyte using a nickel oxide binder suspension, followed by a co-firing process. A mixture of carbon and carbonate was loaded on the 3D anode frame before the fuel-cell assembly.

The as-prepared ceramic textile has good mechanical strength and flexibility, and can be readily applied to numerous electrochemical devices.

Scanning electron microscopy of a calcined 3D anode framework revealed bundles of hollow nickel oxide–GDC fibers knitted together. This porous structure allows penetration of carbon particles. Scanning transmission electron microscopy shows a uniform distribution of nickel and cerium elements, and electron energy-loss spectroscopy shows peaks corresponding to oxygen, nickel, cerium, and gadolinium, indicating that the hollow fibers are composed of nickel oxide and GDC.

A DCFC operating at 500, 550, and 600 °C demonstrates excellent performance with maximum power densities of 143, 196, and 325 mW cm−2, respectively.

The 3D anode framework before loading the carbon fuel shows excellent contact between the hollow fibers and the GDC-carbonate electrolyte. Addition of carbonate to the carbon fuel increases the carbon particle distribution throughout the hollow fibers during operation and extends the triple-phase boundaries region, leading to improved performance.

To find out more about this novel anode for direct carbon fuel cells, please visit the Advanced Materials homepage.