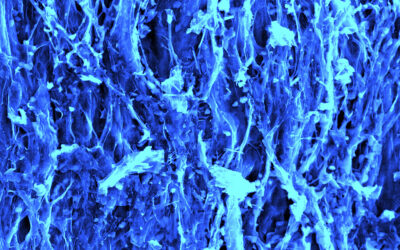

One of the challenges in welding steel with aluminum is to avoid hard and brittle intermetallic phases in the welding seam. These phases can occur easily, since iron and aluminum do not combine well. The goal of scientists at the Laser Zentrum Hannover (LZH), and their partners in the project LaserLeichter, is to control the welding process as much as possible. Therefore, plan to assess different measuring methods.

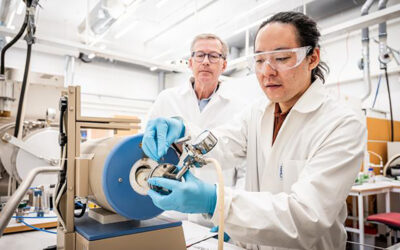

Firstly, the engineers will be testing a spectroscopic control of the welding depth, which measures the emissions of the plasma. During the ongoing process, the composition of the plasma indicates the welding depth, and allows to adapt the laser output accordingly.

This control is already being evaluated for flat welds, and will now be expanded to three-dimensional structures. Since the distance between the process zone and the measurement sensors inevitably changes in the course of the process, detecting the plasma emissions accurately is difficult.

Also, the scientists are testing a sensor made by the project partner Precitec, which can directly measure the depth of the keyhole. Additionally, they are examining a thermal imaging process of the InfraTec, as well as a trailing nondestructive sample analysis using active thermal imaging from the inpro.

The processes developed within the project are tested directly on demonstrators for the automotive industry, for example on a car body element or a battery case.

Apart from the LZH, Precitec, InfraTec and inpro, the following companies are working together in the joint project „Development of a laser-based joining technology for dissimilar lightweight constructions” (LaserLeichter): Volkswagen, Scherdel Marienberg, MATFEM, LUNOVU Integrated Laser Solutions, Brandenburg University of Technology, and Fraunhofer-Institut für Werkstoff- und Strahltechnik. Associated partners in the project are TRUMPF Laser, ASTOR Schneidwerkzeuge, ThyssenKrupp Steel Europe, Bond-Laminates and Sapa Aluminium Profile.

The joint project is coordinated by the Robert Bosch GmbH, and the project management organisation is the VDI Technologiezentrum GmbH.