Applying lubricant in a process called fatliquoring protects leather from cracking. The lubricant penetrates the weave to separate fibers in order to prevent the fibers from rubbing against one another and damaging the material. Fatliquored leather is soft, flexible, and slightly water repellent. Natural fats and waxes are often used as lubricants; however, such materials are susceptible to oxidation and hydrolysis.

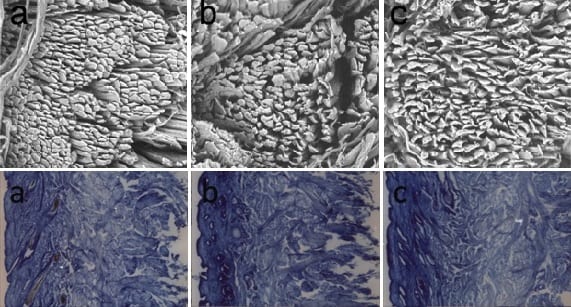

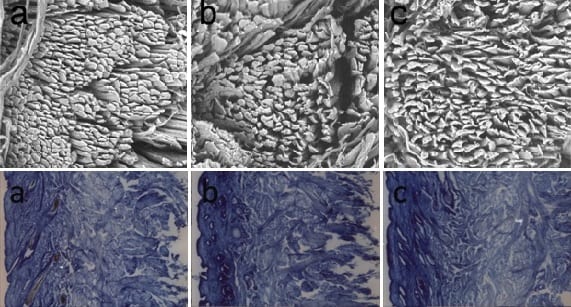

Researchers at Sichuan University have created an alternative to conventional leather lubricants using synthetic copolymers. The copolymers are based on acrylic acid and stearyl acrylate, and contain both hydrophilic carboxyl groups and hydrophobic long alkyl groups, making the copolymers amphiphilic. The hydrophilic groups associate with the collagen in the leather via hydrogen bonding or ionic bonds, while the hydrophobic groups separate the internal fibers. The fiber separation is clearly seen in the SEM micrographs in the below image.

Three samples of leather treated with the amphiphilic acrylate copolymer, showing the separation of fibers (top, SEM graphs) and the penetration of the copolymer stained with Nile blue (bottom, photo).

The molecular weight of the copolymer affects its processing capabilities. Lower molecular weight copolymers (9000–15 000 Da) improve the softness and fiber separation of leather by more easily penetrating the leather surface. Using Nile blue as a visible indicator, the researchers traced the absorption of the copolymer into the leather. As seen in the image above, copolymers with molecular weights under 15 000 Da penetrated the entire sample.

This new lubricant is suitable for use with eco-leather, which is made by layering plant fibers with plant oils rather than using animal skin. The lubricant can be used for both fatliquoring and retanning, reducing the chemicals needed for processing eco-leather to make the fabric even more environmentally friendly.