Biomaterials for tissue engineering applications need to fulfill numerous requirements regarding chemical and physical properties of the material surface, design, function, and biocompatibility. Furthermore, the scaffold serves as a template that directs the formation of tissue. The inner pore network and its outer geometry need to be well-defined to allow cell migration and successful vascularization.

Biomaterials for tissue engineering applications need to fulfill numerous requirements regarding chemical and physical properties of the material surface, design, function, and biocompatibility. Furthermore, the scaffold serves as a template that directs the formation of tissue. The inner pore network and its outer geometry need to be well-defined to allow cell migration and successful vascularization.

To reach these objectives, novel approaches for generating tissue engineering scaffolds focus on rapid prototyping (RP) techniques. Tissue engineering scaffolds, built via layer-by-layer manufacturing processes, can match the in vivo paradigm of porosity and mechanical strength, with an adequate arrangement and design.

Unfortunately, conventional materials already successfully applied as vascular implant materials are not suited for RP processes. There is an immediate demand for new processable biomaterials, which enhance cell adhesion and at the same time meet the requirements of 3D printing processes regarding viscosity and surface tension.

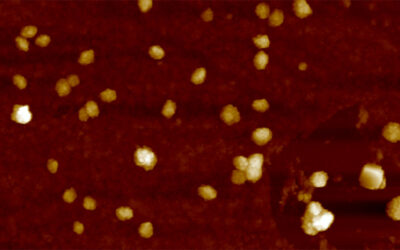

The Fraunhofer Institutes in Stuttgart and Potsdam, together with the Universities of Stuttgart and Würzburg, have developed a biocompatible polyacrylate network for the build-up of artificial tissues through a 3D printing process. The scientists designed two types of polymeric material that meet the rheological requirements for printing processes. They used a soluble biocompatible photoinitiator with good UV curing abilities and compared in a recently conducted study the material characteristics.

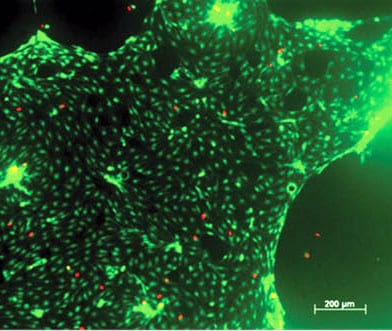

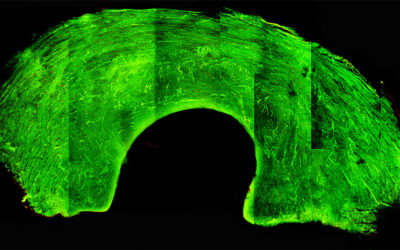

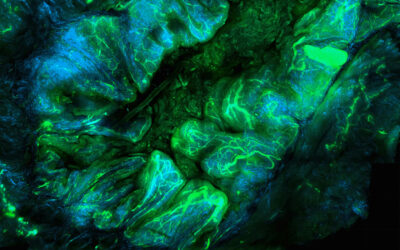

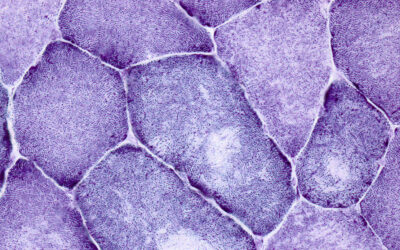

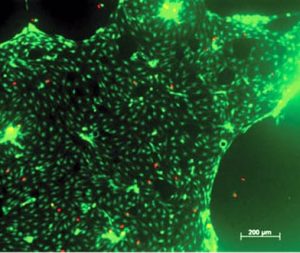

Within this study, the different polymer surfaces were prepared and seeded with a cell culture substrate. By evaluating cell confluence, viability and functionality, the German scientists investigated the cell-material interaction and biocompatibility. They show that the materials are suitable to fulfill the demands of RP processes. Moreover, the polymers revealed remarkable properties for biocoating with the living cells.

Along with its appropriate properties, the novel polymeric blends constitute promising candidates for future scaffold design in tissue engineering. In upcoming work, the scientists will examine the tunable material properties such as tensile modulus and elongation strength and the biocoating with specific cell promoter proteins to enhance the cell adhesion.