The crystallinity of polymers has a huge effect on their properties – a highly crystalline polymer will be very strong, although it’s also likely to be brittle. Adding some amorphous regions increases the polymer’s toughness so that it can bend without breaking. This makes polymer crystallinity a hot topic for researchers looking to control polymer properties for applications.

A simple method to control polymer crystal properties is reported by Rick Register and John Bishop in the Journal of Polymer Science: Polymer Physics. By tuning the polymer tacticity – that is, how the repeat units are oriented to one another – of their hydrogenated polynorbornene (hPN) during synthesis, they are able to produce polymers that can be more easily processed in the solid state, for instance with die compression, to give materials with strongly anisotropic physical properties.

The crystallinity of polymers has a huge effect on their properties – a highly crystalline polymer will be very strong, although it’s also likely to be brittle. Adding some amorphous regions increases the polymer’s toughness so that it can bend without breaking. This makes polymer crystallinity a hot topic for researchers looking to control polymer properties for applications.

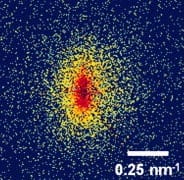

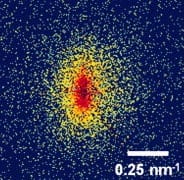

But, as Register explains, it’s not as simple as just being crystalline or amorphous: “Polymer crystals can show degrees of order intermediate between the classical perfect crystal and amorphous liquid.” In this case, at room temperature the researchers’ hPNs change from their entirely three-dimensionally ordered crystal structure to a rotationally disordered crystal phase. In this phase, the polymer chains are much more mobile, so the crystals thicken and grow very quickly during annealing below the melting point making them much easier to process. For instance, using a simple, room-temperature die compression process, one hPN shows twofold higher crystal periodicity and twofold better crystal orientation than a polyethylene treated exactly the same way. The figure shows an X-ray scattering pattern of the processed hPN.

The key to enable this processing is that the researchers are able to stabilize the rotationally disordered phase over a wider temperature range. By making several hPNs with different catalysts, they create polymers of different tacticities. If two repeat units in a polymer are oriented the same way, they’re a meso diad; facing opposite ways they’re described as a racemo diad. Register and Bishop show that by making polymers with a higher ratio of racemo diads they can use them to stabilize their rotationally disordered crystal structure.

“We can easily incorporate hPN into block copolymers –something not so easy to do with Teflon, for example, or with any of the other polymers known to form rotationally-disordered crystals,” explains Register. This means that as the project progresses they will be able to investigate how including the hPNs in block copolymers can tune their properties, too.