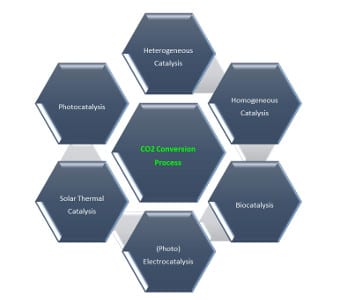

Figure 1. Catalytic processes for converting CO2 into value-added chemicals – which one would you bet on?

The chemical industry are one of the largest manufacturing sectors in the world with global sales currently valued at around $5T. Many of the chemical feedstocks are fossil based and most chemical processes are powered by fossil fuels. They are also one of the largest producers of greenhouse gas and like most of us are concerned about the effect of greenhouse gas emissions on global warming and how they will affect our climate.

In the war now being waged against climate change, there are five big questions being asked by concerned citizens in university, industry, business and government who are motivated by fast, pragmatic and economically sensible solutions to the urgent problem of how best to abate greenhouse gas emissions by utilizing CO2 as a feedstock for manufacturing chemicals, materials and fuels:

- Scaling and Manufacture: what technological strategies for CO2 utilization have the most promise for success in the short term?

- Commercial Potential: what CO2 derived products and uses offer the best opportunities?

- CO2 Footprint: what products and uses can achieve a carbon-neutral carbon-life-cycle?

- Policy Making: what procedures are required to speed the adoption of products and uses based on CO2 as a chemical feedstock?

- R&D Strategy: what areas of CO2 enquiry should be invested in for the long-term?

To realise a technologically, economically and sociologically acceptable solution to the abatement of greenhouse gas emissions, five commandments for utilization of CO2 as a chemical feedstock have been mandated, as a replacement for fossil based feedstocks and fuels in chemical industrial processes:

- Reduces overall CO2 emissions

- Lowers materials and energy intensity

- Employs safer conditions

- Operates on a commercial scale

- Demonstrates economic viability

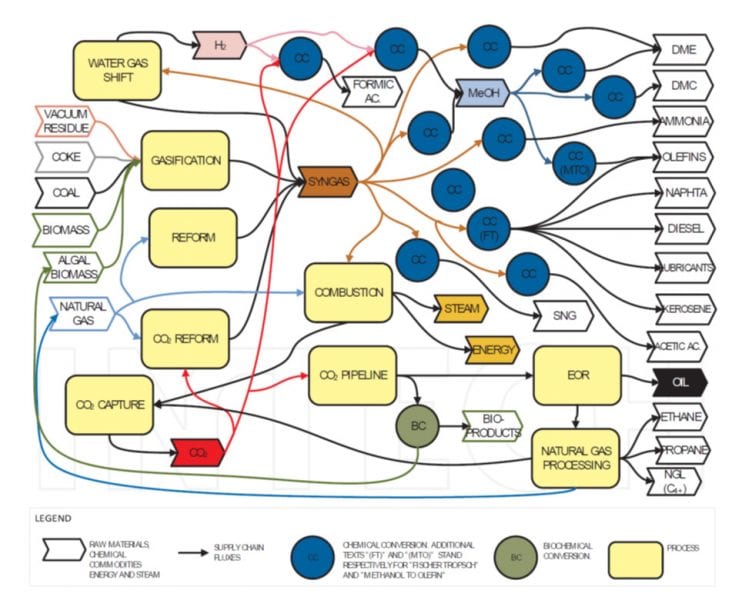

Figure 2. Chemical industry supply chain flow diagram depicting the coexistence of fossil and biomass feedstock uses and how CO2 capture and utilization can be integrated into existing production infrastructure. Reproduced with permission from CO2 Utilization: A Process Systems Engineering Vision by Ofélia de Queiroz F. Araújo, José Luiz de Medeiros and Rita Maria B. Alves under the terms of the Creative Commons Attribution License.

In this context, the chemical industry have been asking how CO2 capture, utilization and valorization fits into the current supply chain, which comprises about 40,000 chemicals produced from the four traditional feedstocks: oil, gas, coal and biomass. The perception of the chemical industry is that their CO2 emissions are expected to expand and that treating CO2 as a non-traditional feedstock, viewed as an asset rather than a liability, will help enable a transition to low-carbon processes based on existing infrastructure.

The opinion of the chemical industry seems to be that incorporation of CO2 as a feedstock into their supply chain is most likely to be expected initially in mature technologies that focus on the production of the key chemicals carbon monoxide, hydrogen, olefins, aromatics, ammonia, methanol and hydrocarbon fuel, see Figure 2. Notably, this change will require the rapid development of enhanced activity and selectivity catalysts that will facilitate advances in chemical process performance, intensification and optimization.

The chemistry challenge to achieve these goals relates to how to overcome the exceptional stability of the CO2 molecule, measured by its high free energy of formation of 394 kJ/mole. Its high thermodynamic stability means that high input of electrical, thermal or solar energy together with very active catalysts are required for any chemical conversion of CO2 to a value-added product.

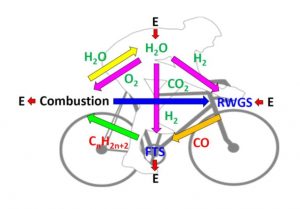

Figure 3. Carbon-neutral carbon cycle for making hydrocarbons from carbon dioxide and water.

In this light, there are six main catalytic CO2 conversion processes currently under active investigation all vying for a stake in the race to utilize and valorize CO2 as a supply chain feedstock for producing chemicals and fuels, Figure 1. Recall that the role of catalysts is to lower the activation energy barrier for chemical reactions in order to accelerate their rates and allow them to occur under much milder conditions.

Specifically, in the case of large volume production of chemicals from CO2, which has to be accomplished at the megaton level to meaningfully impact climate change, the discovery of high performance catalysts is especially important to achieve processes with a low carbon footprint, high energy efficiency and economies of scale.

The goal of every catalytic CO2 conversion method illustrated in Figure 3 for the case of hydrocarbons, is to provide carbon neutral alternative and sustainable sources of chemicals, polymers, pharmaceuticals and fuels. A big question however, concerns which are the preferred methods for innovative game-changing research to drive future technology development and commercialization? The answer to this question will enable decisions on which methods are ready to be accelerated through to pilot scale demonstration units, in order to facilitate the replacement of existing processes based on traditional oil, gas, coal and biomass chemical feedstocks, with sustainable processes founded on CO2.

In this respect, an important initial target will involve the heterogeneous catalytic conversion of gaseous CO2 into synthesis-gas CO/H2, as it is an appealing feedstock for making key chemicals, such as NH3, H2, CO, CH3OH and CnH2n+2 and moreover makes use of existing tried-and-true chemical industry infrastructure.

To amplify, in the case of hydrocarbon fuels, this can be achieved in a carbon-neutral carbon-cycle of the kind shown in Figure 2. The cycle begins with H2O as a source of H2 followed by use of the H2 to reduce CO2 in a reverse water gas shift process to form CO, which is then used to make hydrocarbons in a Fischer-Tropsche process. A similar cycle can be devised for making important chemicals and fuels exemplified by methanol, dimethylether, dimethylcarbonate, olefins, naphtha, diesel, lubricants, acetic and formic acid.

In terms of the short term industrialization of CO2 one can draw the following conclusions:

- CO2 is a promising and sustainable feedstock for the chemical industry

- CO2 conversion to chemicals and fuels is at an early stage of development

- CO2 utilization is currently a very small fraction of greenhouse gas emissions

- CO2 most likely will integrate into the chemical industry supply chain and processing infrastructure as synthesis gas derived products, hydrogen, carbon monoxide, methanol, ammonia, and synthetic fuels.

These indicators imply that the future looks bright for the exploration and development of innovative CO2 chemistry solutions to enable a sustainable chemical industry that will help mitigate climate change, reduce our dependency on fossil fuels, and enhance our protection of the environment. The development of these solutions is essential if the chemical industry are to reduce their carbon emissions and achieve the emission reduction targets imposed on the chemical industry in the next few years. They cannot achieve these targets by carbon efficiency measures alone.

In order to achieve these innovative CO2 chemistry solutions, it is also essential that there be cooperation between the research community, the chemical industry and governments so that the necessary investment is available for pilot scale demonstration units and ultimately the scaling up of the winning units to a megaton commercial level. The expertise of the chemical industry will also be important with regard to the latter. It may be that there should be incentives for those chemical companies who are proactive in supporting and financing the pilot scale demonstration units required and ultimately the scaling up of units to a megaton commercial level.

In closing, it is worth noting that whichever greenhouse gas mitigation, reduction and utilization action plans are adopted to hold global temperature rise below 2°C, a successful outcome can only be assured if CO2 emissions are monitored at local, regional and national levels, and legal and policy measures implemented to enforce compliance with CO2 emission targets.

Postscript from Industry

I will end this article with a postscript on some sobering words of wisdom from a friend and colleague in the chemical industry, who read this opinion editorial and offered the following remarks:

There is a lot going on in the chemical industry. They are continuously working on lowering the energy footprint of every one of their products and processes. The impact of implementing energy saving technologies in the chemical industry would reduce energy usage throughout the world significantly, which amounts to a lot of CO2 but is only a partial solution to climate change.

The solution proposed in your editorial will require governments to enact legislation that makes CO2 generation too expensive to sustain without converting it to something valuable. This is because the technologies needed to convert CO2 to something of value have to pay off and ultimately be self-sustaining mid to long term for major corporations to get involved. If the senior management of corporations tried to altruistically invest in CO2 conversion without a compelling business case, they would be replaced before they got very far!

The solution to this problem is a difficult balancing act that will likely involve legislation, start-ups who see the dollars that eventually will come with saving the world, VC’s who are willing to gamble and wait, and finally major corporations getting into the act when they can see past the risk to a business.

This is probably not what you wanted to hear, but most people, including voters, look into their pocketbooks and their lives and vote and spend accordingly. Solving the climate change crisis will require nothing less than global lifestyle changes, rather than most inhabitants of every developing country wanting to live like Americans, Europeans, or Britains.

It’s interesting that what is needed is a sort of “conversion experience”, where people suddenly look past their own needs to those of their grandchildren. It likely means that most of us will have to live more like those in the developing world. This “conversion experience” may be brought about by scientific proselytizing, but will enough of the public be converted to result in change? I can see the challenge here; people mostly don’t change when they see the light, but when they feel the heat – perhaps literally in this case.