Today’s solar cell research is mainly driven by two, often contradicting, motivations – the race to higher efficiency and the need to reduce the manufacturing costs.

The heterojunction concept has been proven to have outstanding efficiencies, and to achieve cost-effectiveness by potentially omitting the high-temperature process steps during manufacturing.

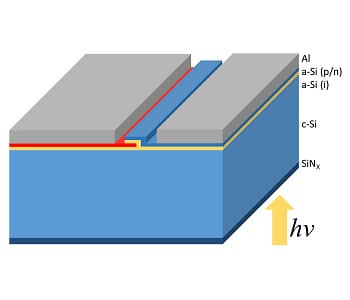

On the one hand, heterojunction solar cells allow for very high open circuit voltages (VOC) by the use of crystalline silicon wafers, which are passivated by amorphous silicon materials. On the other hand, the light absorption of these cells can be maximized by employing the back contact (BC) cell concept, where both contact types are placed at the back of the cell, thus eliminating shading losses. The combination of these two concepts results in very high power conversion efficiencies.

In a recently published article in Solar-RRL, scientists present back contact silicon heterojunction solar cells featuring two different contact schemes; the commonly used contact stack consisting of indium tin oxide and silver (ITO/Ag), which preserves the high VOC values but introduces transport losses across the amorphous silicon (a-Si)/ITO interface, is replaced by a much cheaper aluminum (Al) contact.

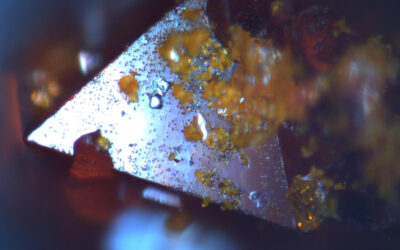

However, annealing this Al contact at a temperature of 150 °C for several minutes initiates a diffusion process between the aluminum and the underlying a-Si layer, which drastically decreases the resistivity of the contact, but also leads to more recombination and thus a lower VOC. This authors overcome this hurdle by finding the right trade-off, namely, demonstrating that the superior transport properties can overcompensate for the losses in VOC, making the Al contact overall more efficient than the conventional ITO/Ag contact. Furthermore, the manufacturing costs are reduced, since aluminum is cheaper than ITO and Ag, and also, the process complexity is reduced by avoiding one deposition step.

Therefore, aluminum can be regarded as a viable alternative to the established ITO/Ag contact stack, bringing the back contact silicon heterojunction solar cells to the next level.